100% Customization – Perfectly Tailored to Your Production Needs

Our Professional Team Is Always Ready to Solve Any Issues.

What types of containers do you plan to use for filling?

The after-sales services and technical support offered by Sunter team.

What are your target volume, hourly output, and preferred filling system?

Discover Sunter's Expertise Through Our Proven Machinery Cases.

Find answers to common questions to help you make an informed purchase.

Filling Accuracy:±1%

Filling Head:12-24(optional)

Filling Speed:3000-14000 BPH(500g)

Filling Accuracy:±1%

Filling Head:8-24(optional)

Filling Speed:2000-12000 BPH(500g)

Filling Accuracy:±1%

Filling Head:12-24(optional)

Filling Speed:3000-12000 BPH(500g)

Filling Accuracy:±1%

Filling Head:12-24(optional)

Filling Speed:3000-12000 BPH(500g)

Filling Accuracy:±1%

Filling Head:12-24(optional)

Filling Speed:3000-11000 BPH(500g)

Filling Accuracy:±1% Filling Head:2-12(optional) Filling Speed:500-4000 BPH(500g)

Filling Accuracy:±1%

Filling Head:2-12(optional)

Filling Speed:500-4000 BPH(500g)

Filling Accuracy:±1%

Filling Head:2-12(optional)

Filling Speed:500-3000 BPH(500g).

Filling Accuracy:±1%

Filling Head:2-12(optional)

Filling Speed:500-3000 BPH(500g)

Bottle material: glass, plastic, adaptable to various materials

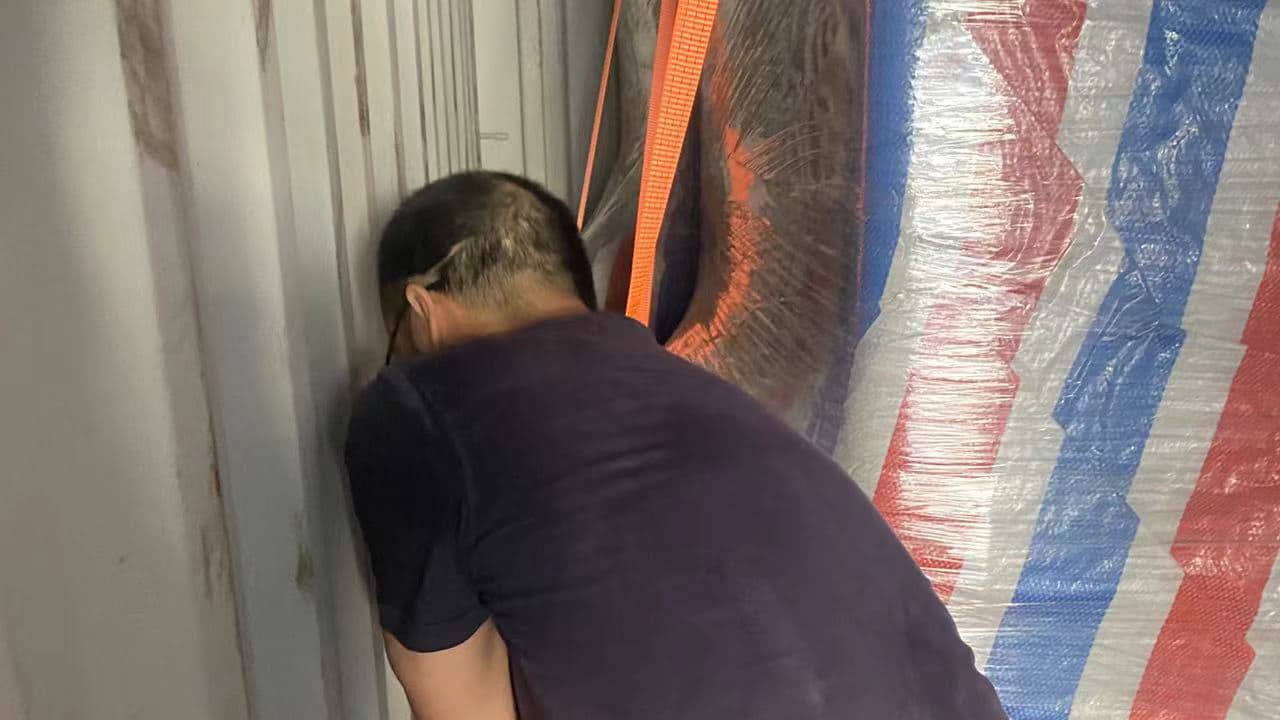

All machines are securely packed in export-grade wooden cases. We work with trusted logistics partners to ensure safe, on-time delivery by sea, air, or land.

We provide clear installation guidance and hands-on training to ensure your team can operate the machine with confidence and efficiency from day one.

We offer a one-year warranty with full technical support, quick response, and spare parts assistance to keep your production running smoothly.

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia.

Thank you for your interest. If you have any inquiries, please fill out the form below. We will get back to you within 24 hours.

Thank you for your interest. If you have any inquiries, please fill out the form below. We will get back to you within 24 hours.