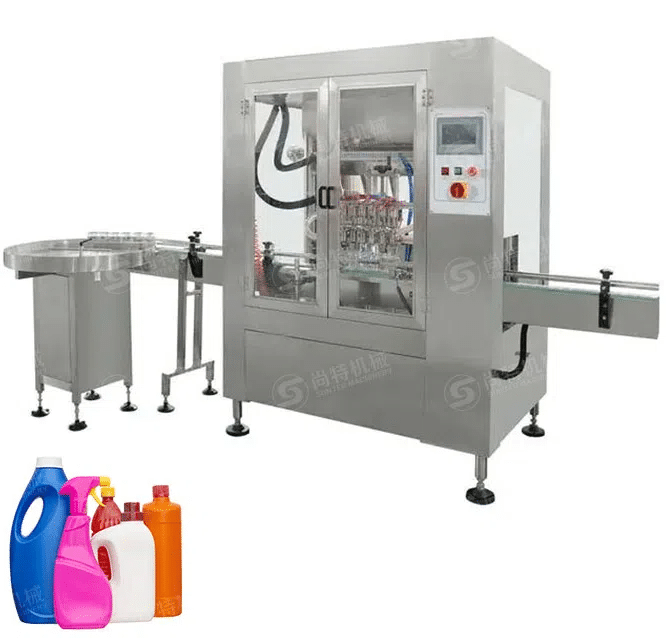

Serving Food Manufacturers Worldwide with Precision Filling Solutions

Edible Oil Filling Machine Series

Edible Oil Filling Machine Series delivers accurate, automated filling solutions for various containers.Designed for soybean oil, sunflower oil, palm oil, olive oil, and more, this series meets diverse production needs.

Thick Sauce Filling Machine Series

Thick Sauce Filling Machine Series is designed for all types of sauces, including chili, tomato, garlic, and meat sauces.Designed specifically for thick sauces, this filling machine ensures smooth, drip-free filling.

Honey & Syrup Filling Machine Series

Honey & Syrup Filling Machine Series is specially engineered for high-viscosity liquids, ensuring precise and drip-free filling. Equipped with advanced volumetric systems, it minimizes product waste and reduces production downtime.

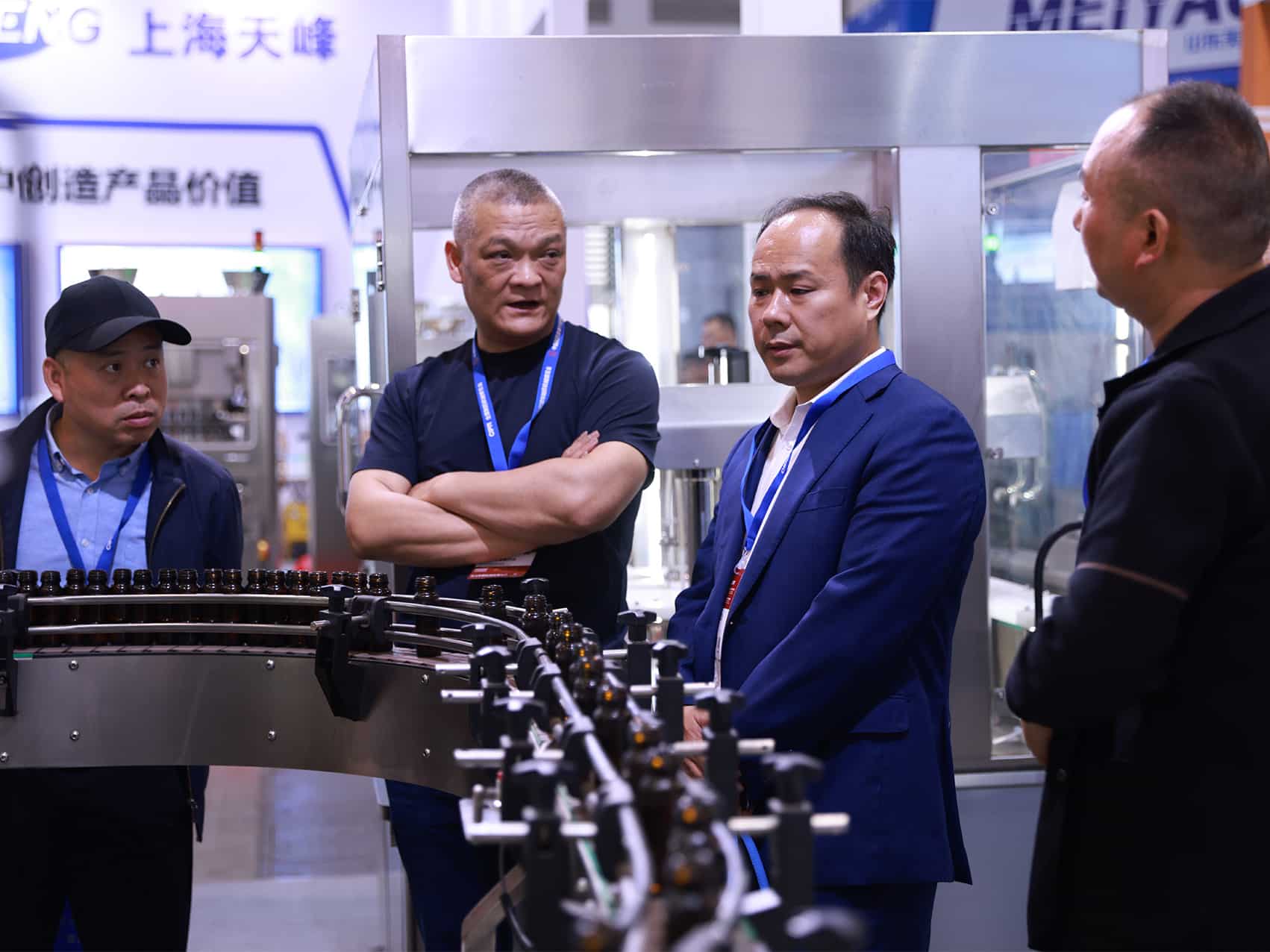

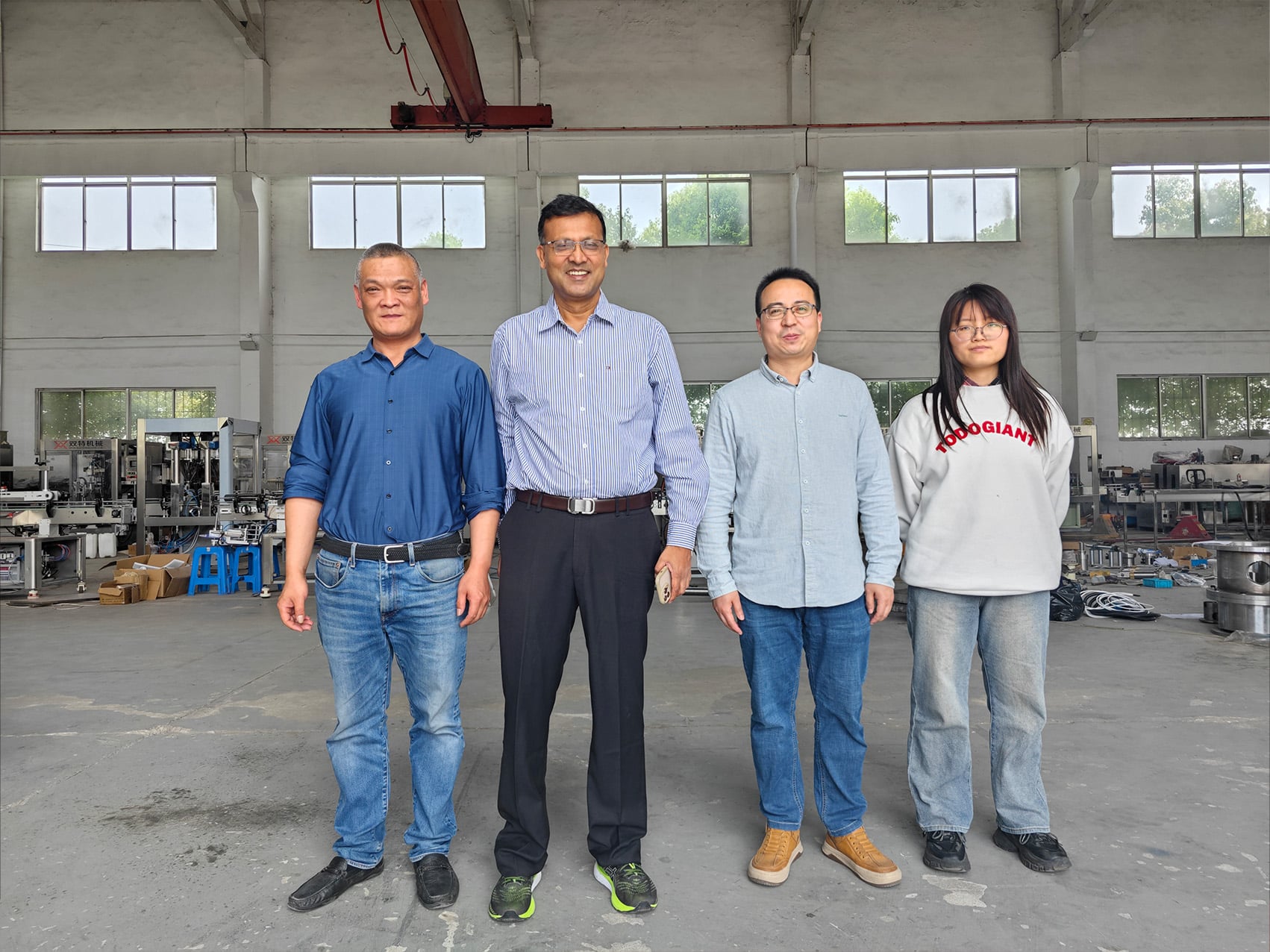

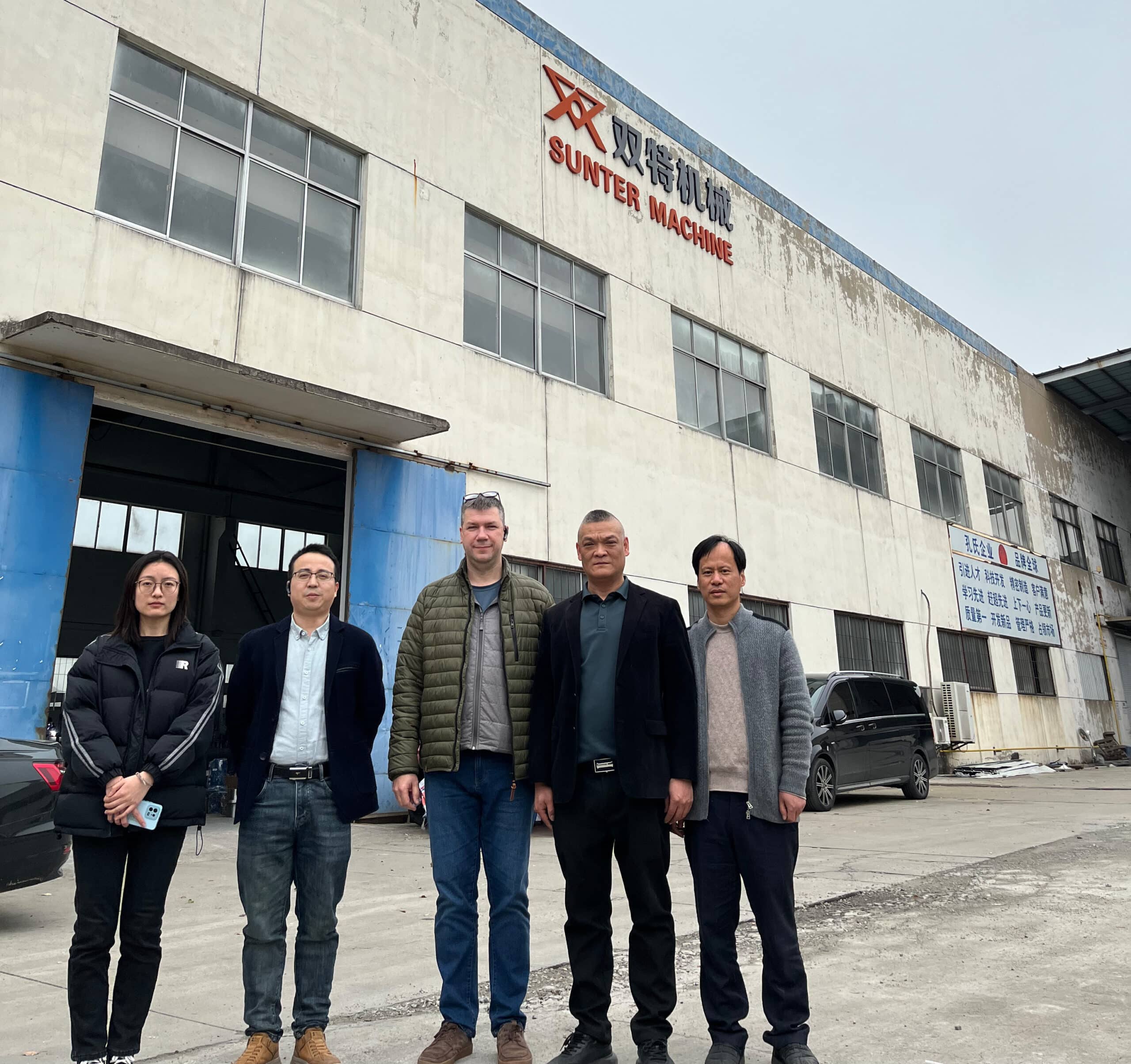

Corporate Trust Us

Your Trusted Expert in Turnkey Filling Lines From China

20+ Years Of Experience

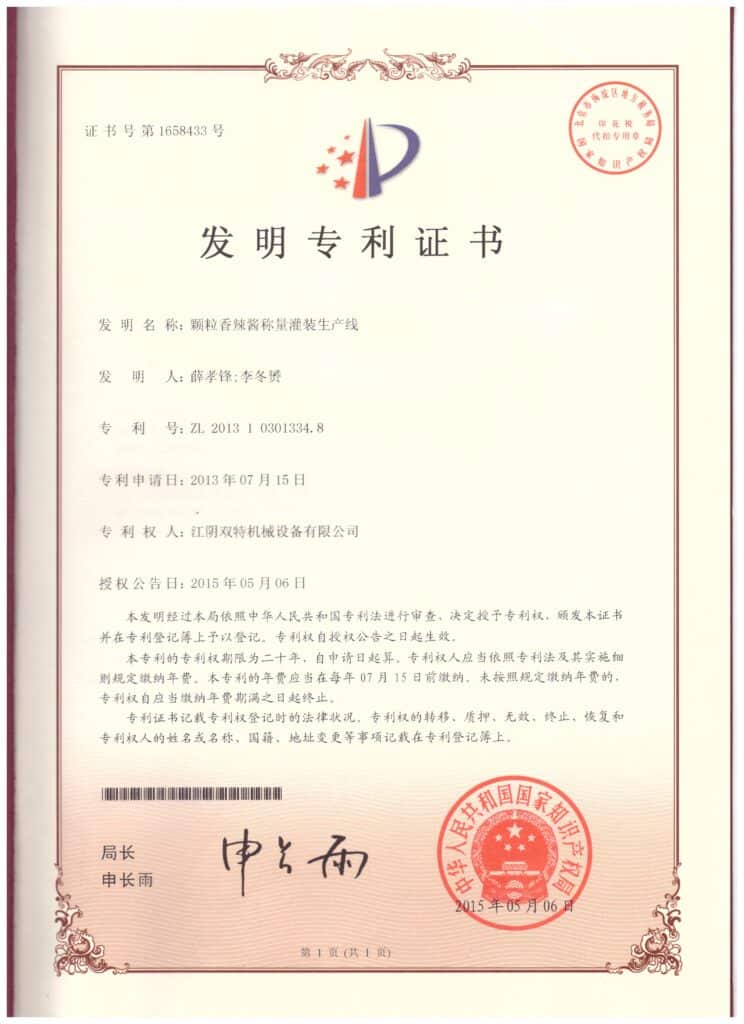

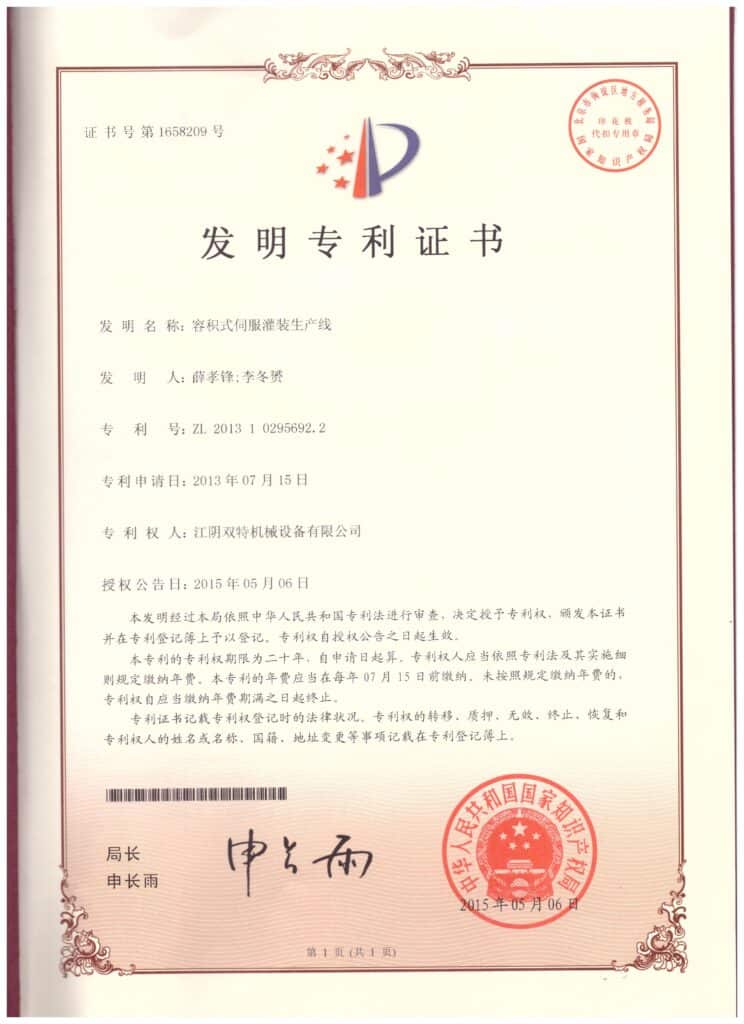

14 Patent Certifications

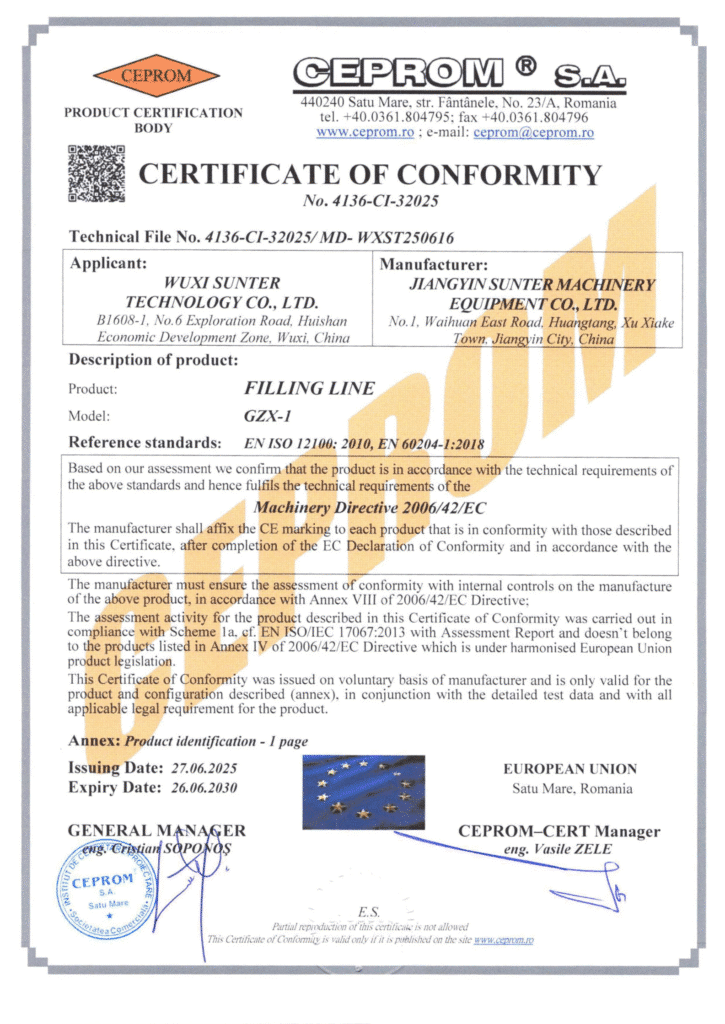

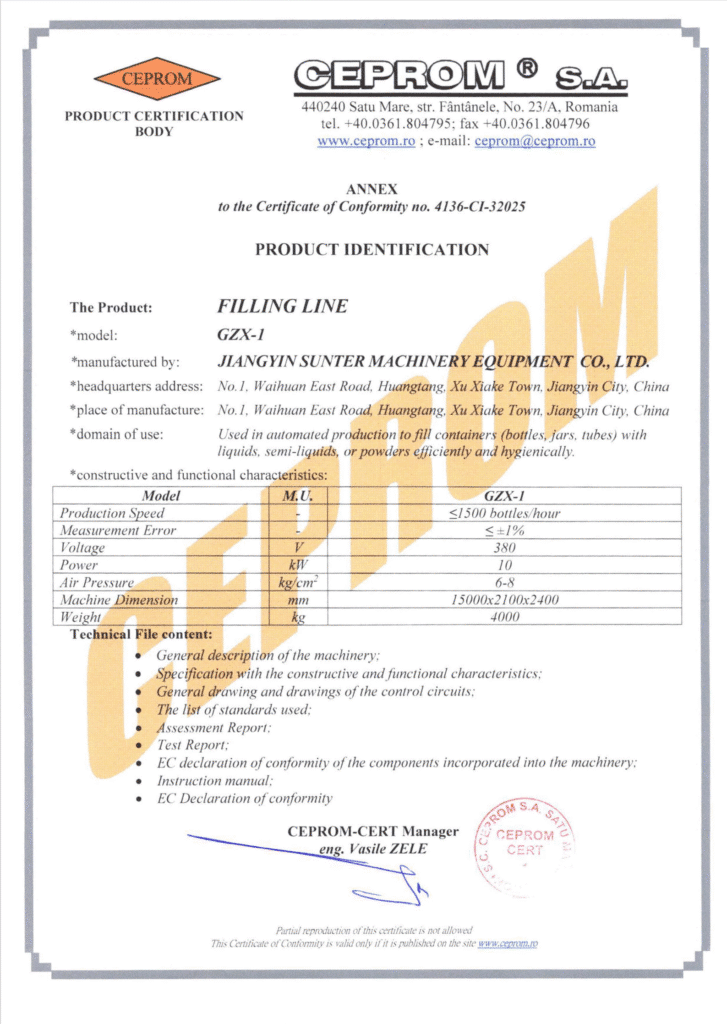

CE Certified

From Empty to Ready —

Automated Bottle Preparation Solutions

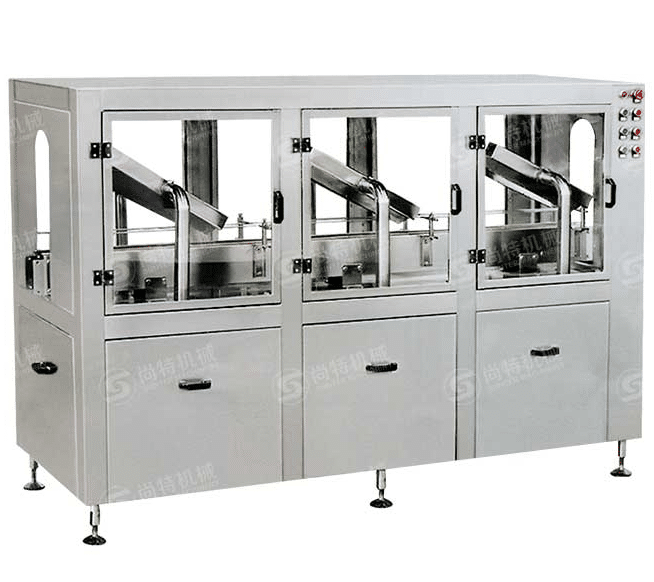

Bottle unscrambler

Eliminate manual bottle handling and ensure a continuous, streamlined flow of containers to your filling equipment.

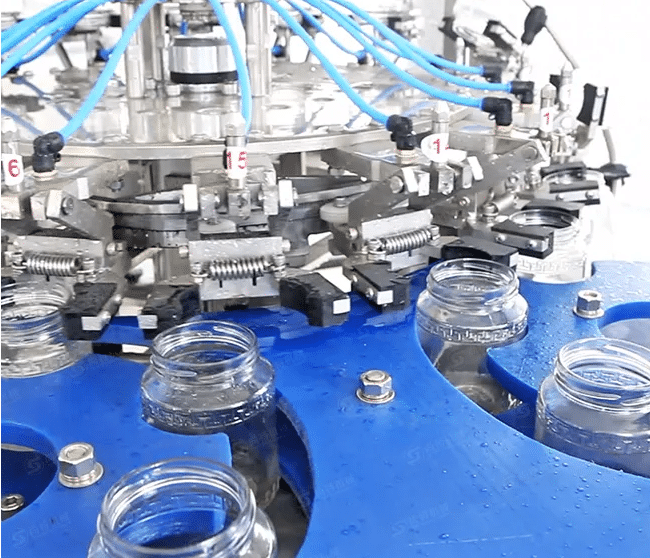

Bottle washer

Our Bottle Washers offer efficient and consistent cleaning, integrating seamlessly into your existing filling line.

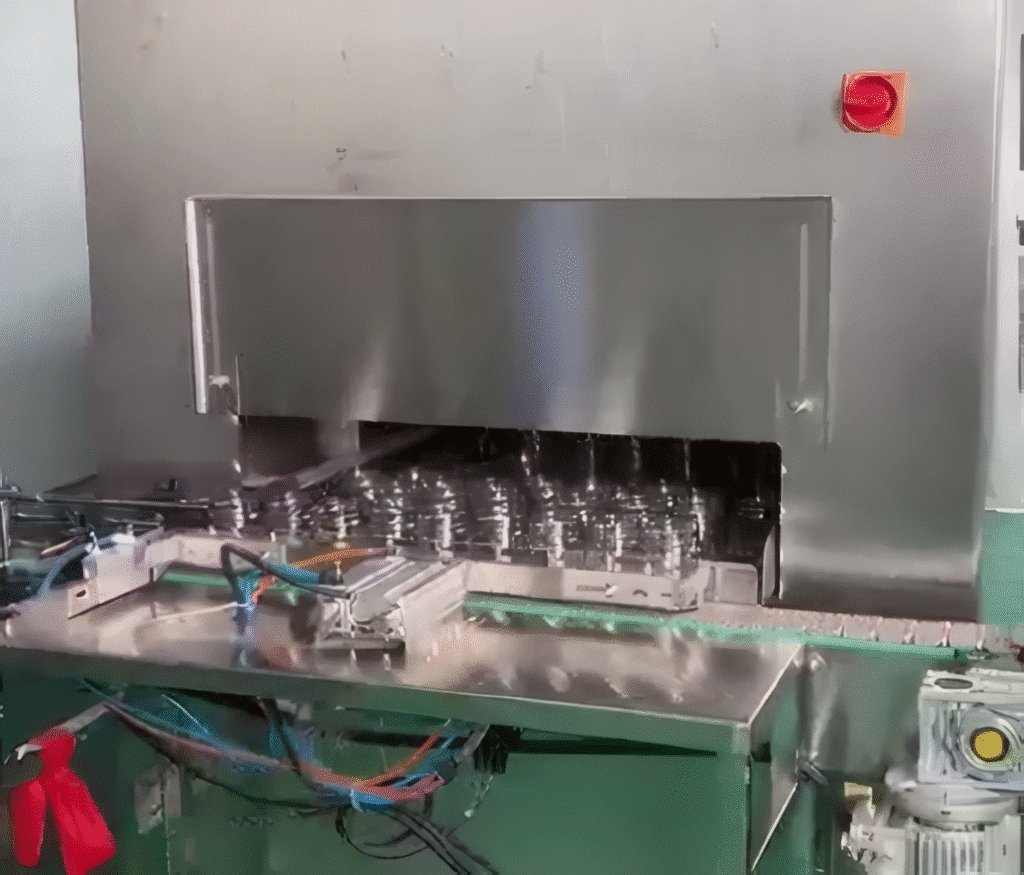

Sterilization tunnel oven

The sterilizing tunnel oven dries and sterilizes cleaned containers, ensuring they are germ-free before filling and extending shelf life.

End-of-Line Equipment for Filled Products

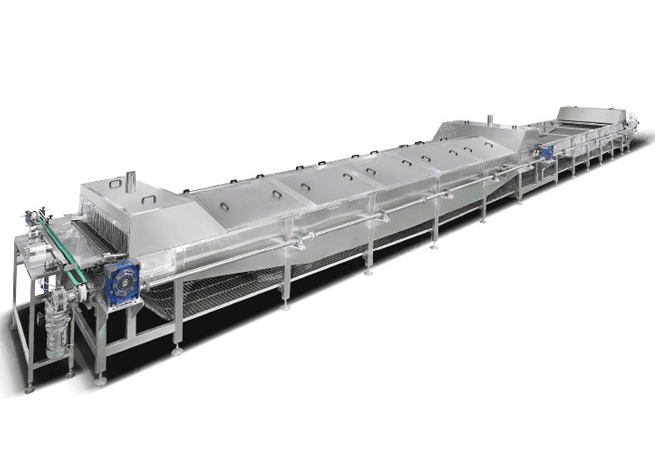

Pasteurization Equipment

Our pasteurization equipment effectively eliminates harmful microbes, ensuring product safety and longer shelf life. Precise temperature control guarantees consistent pasteurization results.

Air Knife Drying System

This air knife drying system removes surface moisture from bottles after pasteurization, ensuring smooth labeling.and packing It features adjustable airflow and easy-to-maintain components.

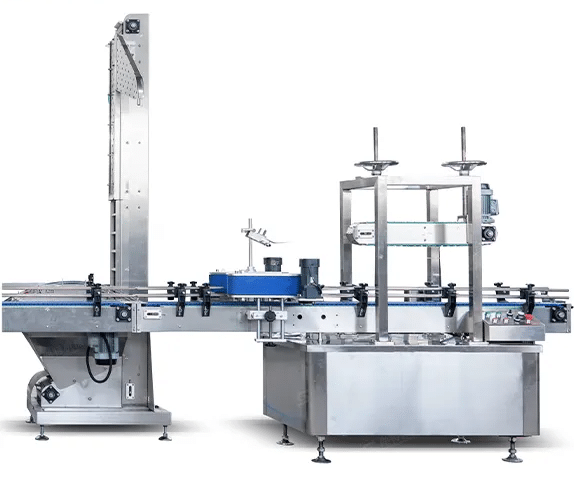

Capping Machine

Highly adaptable, capable of handling various cap types, bottle sizes, and materials. Available in automatic models, it can be integrated with filling machines to enhance productivity.

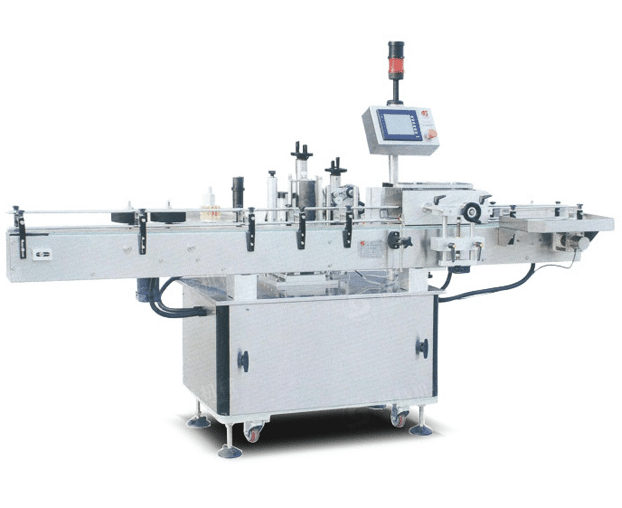

Labeling Machine

Labeling machine handles various containers such as round, square, and flat bottles, efficiently applying labels of different sizes, shapes, and materials.With a compact design and user-friendly operation.

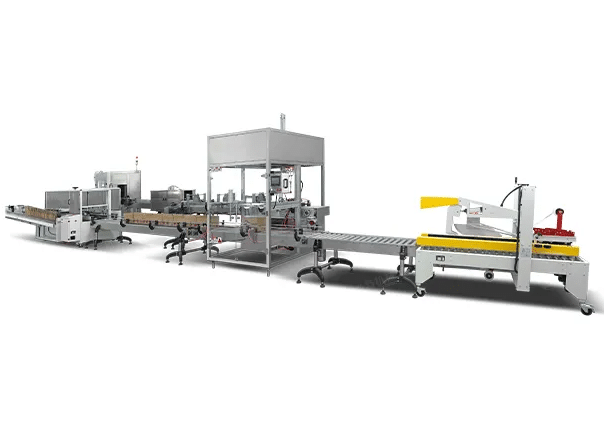

Packing Machine

Packaging machines streamline end-of-line processes, greatly boosting packing speed and reducing labor costs. Options include shrink wrap machines, fully automatic cartoon packing,to meet various packaging needs.

Palletizing Equipment

Palletizing system automatically stacks products onto pallets, significantly improving end-of-line efficiency. Designed for heavy loads and high throughput, it ensures stable and secure pallet configurations.

Stay ahead of the curve with our thought-provoking content

Are your standard filling machines struggling with aggressive, viscous, or foamy chemicals?

Filling difficult chemicals causes constant problems. These issues lead to costly downtime and product loss. The solution lies in a system designed specifically for your material’s unique properties. A truly effective filling solution respects the material’s unique characteristics. It means tailoring every component—from pumps and valves to control logic—to handle aggressive, high-viscosity, foamy, or shear-sensitive […]

Choosing a Small Bottle Filling Machine: Throughput or Flexibility?

Choosing a new filling machine feels overwhelming. You need speed for output, but you also need flexibility for new products. The wrong choice can cripple your growth and waste money. The best choice isn’t about throughput versus flexibility. It’s about finding a dynamic balance. You must tailor the machine to your company’s current needs, product […]

How Can You Minimize Foaming During High-Speed Carbonated Filling?

Is excessive foaming slowing down your high-speed carbonated filling line? This costly problem wastes product and hurts efficiency. You can fix it by mastering temperature, pressure, and flow control. To minimize foaming, you must strictly control four areas. Maintain a stable, low filling temperature. Ensure the filling valve design promotes smooth, laminar flow. Use multi-stage […]

Ready To Boost YourProductivity?

Contact Form

Thank you for your interest. If you have any inquiries, please fill out the form below. We will get back to you within 24 hours.