Carton Palletizing and Conveyor System

Automated palletizing solutions, including robotic palletizers and conveyor systems, streamline end-of-line processes by efficiently stacking packaged goods onto pallets.

Your One-Stop Manufacturers For Carton Palletizing and Conveyor System

Non-Standard Customization

100% Customization – Perfectly Tailored to Your Production Needs

12-Hour Online Support

Our Professional Team Is Always Ready to Solve Any Issues.

Customize Your Carton Palletizing System in Just 5 Steps!

Step 2 Let us know the bottles, caps, and containers you intend to fill

What types of containers do you plan to use for filling?

Step 4 Dedicated After-Sales Support to Ensure Worry-Free Production

The after-sales services and technical support offered by Sunter team.

Step 1 Define Your Filling Capacity and Machine Requirements

What are your target volume, hourly output, and preferred filling system?

Step 3 Explore Real Custom Projects by Sunter – Direct from Our Factory Floor

Discover Sunter's Expertise Through Our Proven Machinery Cases.

Step 5 Customer FAQs – Everything You Want to Know Before Ordering

Find answers to common questions to help you make an informed purchase.

step 1

Explore Our Carton Palletizing and Conveyor System

'BPH' = Bottles Per Hour (filling capacity).

Column-Type Automatic Palletizing Machine

Operational capacity : 8 units per minute

(For reference only. The actual situation shall prevail)

Collaborative Robot Palletizing System

Operational capacity : 8 units per minute

(For reference only. The actual situation shall prevail)

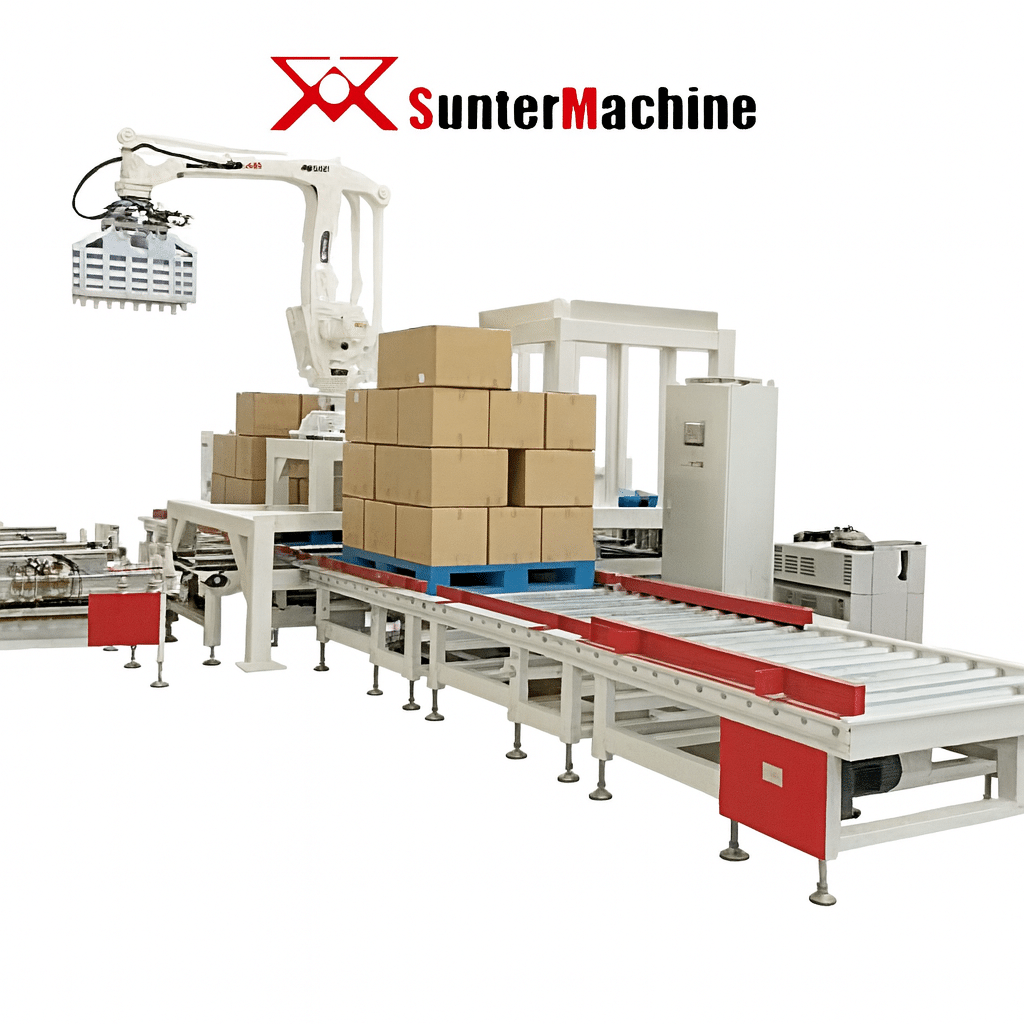

Robotic Arm Palletizer (Articulated Type)

Operational capacity : 8 units per minute

(For reference only. The actual situation shall prevail)

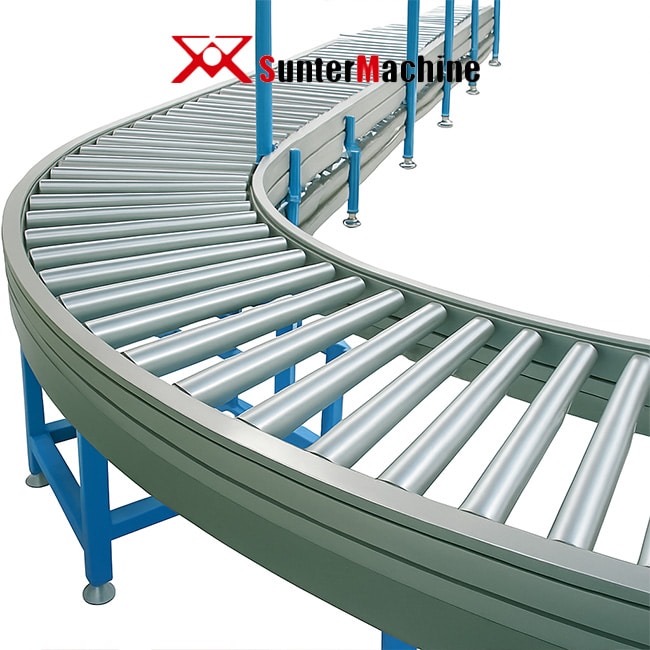

Carton roller conveyor machine

Operational capacity : 20 units per minute

(For reference only. The actual situation shall prevail)

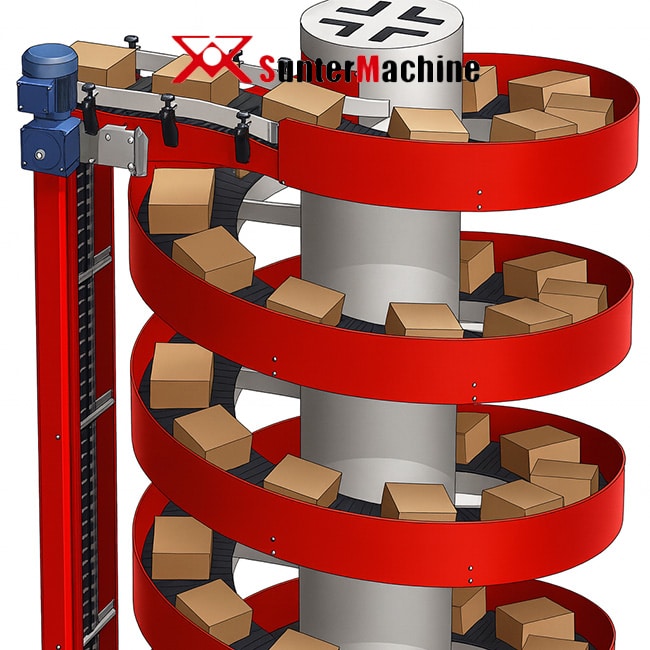

Vertical conveying of cartons machine

Operational capacity : 8 units per minute

(For reference only. The actual situation shall prevail)

Inclined belt conveyor machine

Operational capacity : 8 units per minute

(For reference only. The actual situation shall prevail)

Step 2

Tailor-Made Machines Based on Your Carton Type – Precision Built for Your Product

Corporate Trust Us

step 3

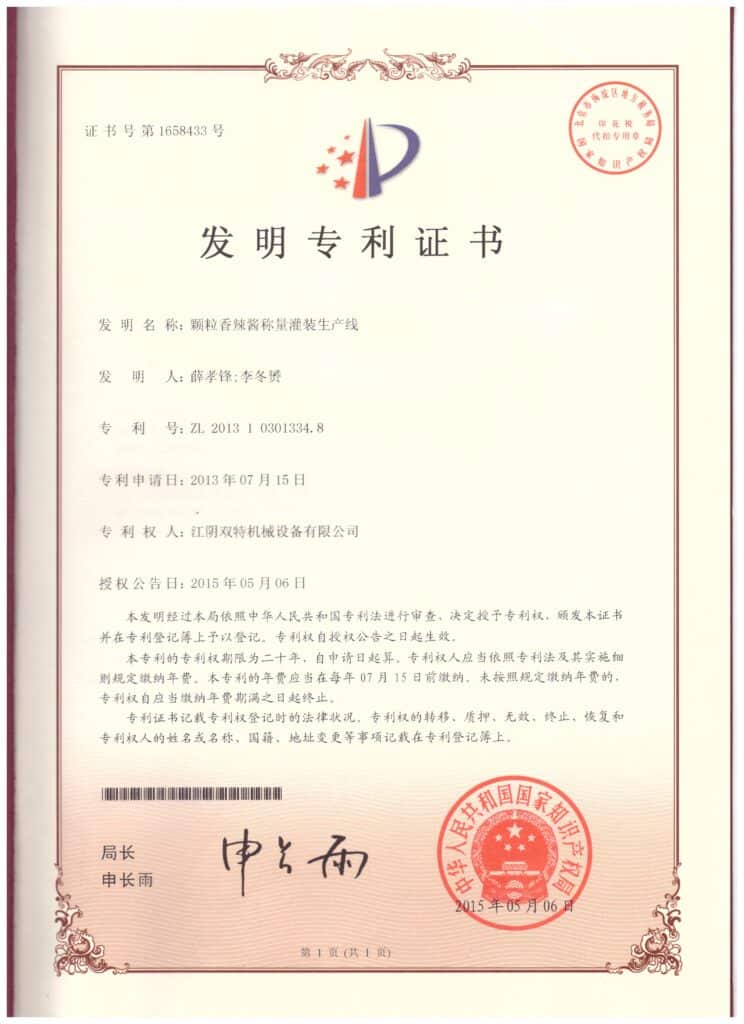

Your Trusted Expert in Turnkey Filling Lines From China

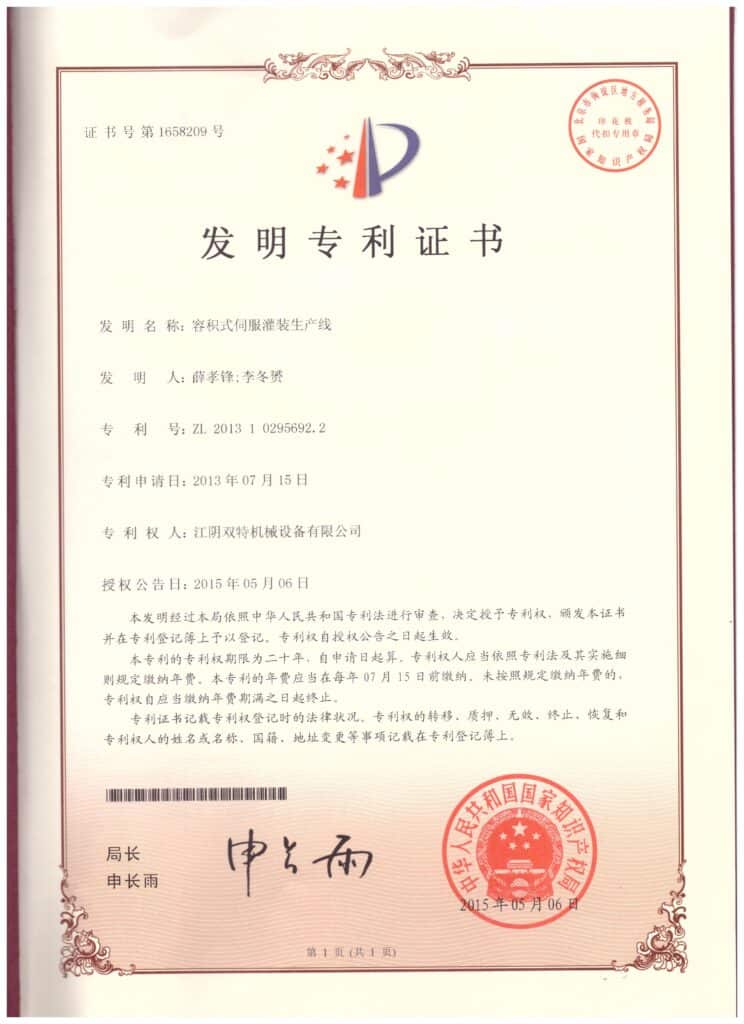

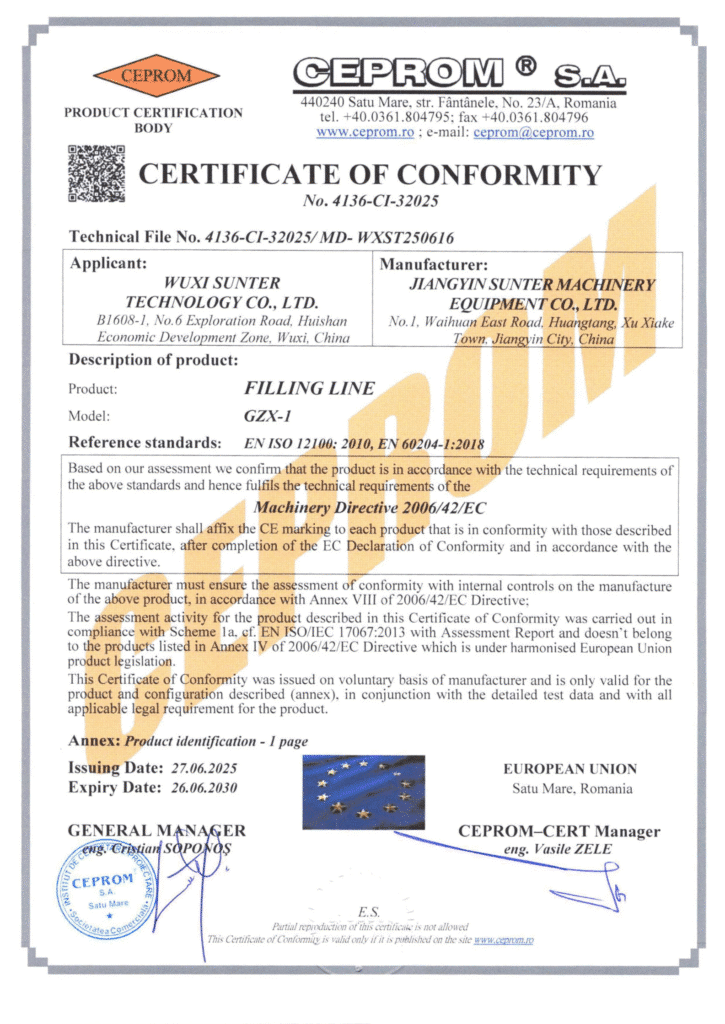

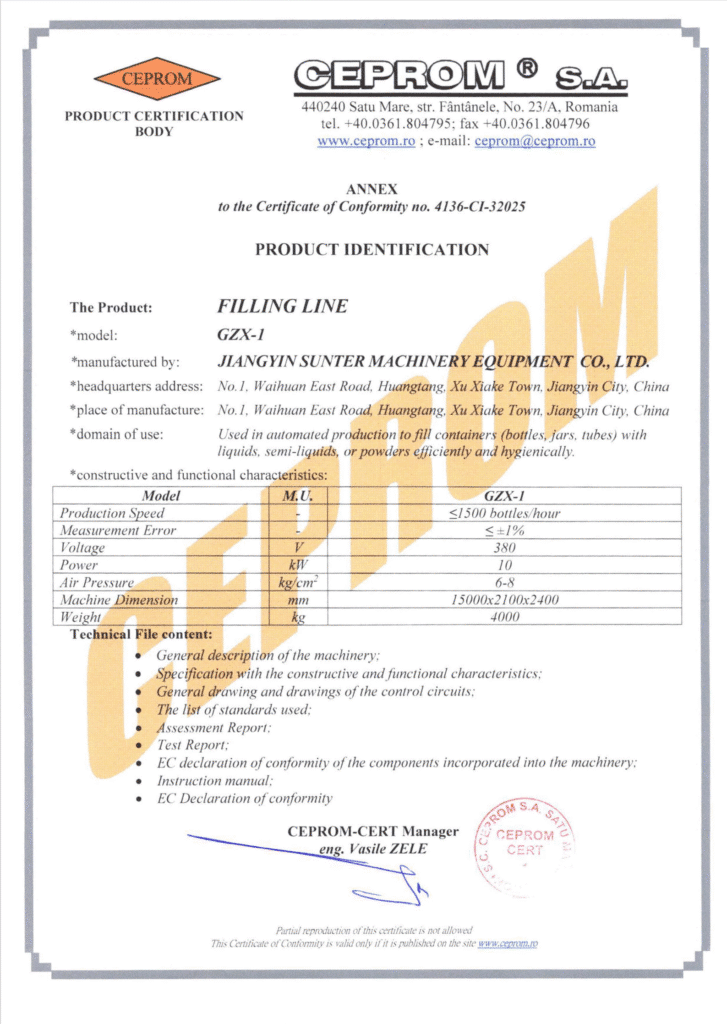

20+ Years Of Experience

14 Patent Certifications

CE Certified

step 4

From Factory to Your Door – Hassle-Free Logistics Solutions

Packaging and shipping service

All machines are securely packed in export-grade wooden cases. We work with trusted logistics partners to ensure safe, on-time delivery by sea, air, or land.

precision installation and usage training

We provide clear installation guidance and hands-on training to ensure your team can operate the machine with confidence and efficiency from day one.

1-year full after-sales service

We offer a one-year warranty with full technical support, quick response, and spare parts assistance to keep your production running smoothly.

step 5

Customer FAQs – Want to Know More? Get in Touch with Us!

* **Optimized Stacking Patterns:** We recommend using staggered or interlocked stacking methods to distribute weight evenly and reduce the risk of collapse.

* **Non-Slip Solutions:** Incorporating non-slip pallets or adding interlayer dividers helps prevent shifting during handling and transportation.

* **Integrated Detection Systems:** Our palletizing systems can be equipped with visual inspection cameras or pressure sensors to detect and automatically correct deviations in real time.

* **Clean guide rails and sensors regularly** to maintain accurate positioning and reliable detection.

* **Lubricate mechanical components** according to the maintenance schedule to minimize wear and ensure smooth operation.

* **Inspect pneumatic components** (if applicable) for air leaks, pressure inconsistencies, and general wear to avoid downtime.

* **Update control software and system firmware** periodically to benefit from the latest performance optimizations and safety enhancements.

Startups and Pilot Projects: Perfect for businesses launching new products or entering the market with a single machine.

Small to Medium Enterprises: Ideal for customers upgrading a portion of their production line or scaling operations gradually.

Custom Single Machines: Even a single machine can be customized to suit specific formulations, container types, and product formats.

Whether you need a fully integrated production line or a standalone machine, we are committed to providing high-performance, reliable solutions tailored to your exact needs.

* **Voltage:** (e.g., 220V, 380V, 415V)

* **Frequency:** (e.g., 50 Hz or 60 Hz)

* **Phase:** Single-phase or three-phase

We support standard power configurations used throughout Europe, North America, Asia, and the Middle East. For regions with unique or unstable power conditions, we offer the option to incorporate voltage stabilizers or transformers into the system design.

* **Wearing Parts and Operation Video:** Each shipment includes one year's supply of essential wearing parts, along with a detailed operation tutorial video to assist with installation, setup, and routine use.

* **Operator Training:** We provide thorough training programs for your personnel, covering equipment operation, basic maintenance procedures, and common troubleshooting techniques.

* **Technical Support:** Our technical team offers responsive support through phone, email, and remote diagnostic tools to help resolve any operational challenges promptly.

* **Warranty Support:** Sunter Machinery provides lifetime maintenance support for all equipment. During the one-year warranty period, we will repair or replace defective components at no cost, except for shipping charges. This warranty excludes damage caused by misuse, human error, or vandalism, as well as consumables and wear parts.

To provide a more precise production and delivery schedule tailored to your project, we kindly request the following information:

* **Detailed container specifications:** Exact dimensions (length, width, and height) of cartons, bottles, caps, or closures.

* **Line configuration:** Desired layout and any specific functional modules to be included.

* **Production requirements:** Target throughput (e.g., bottles per hour, capacity per bottle).

Several factors may influence the final delivery timeline:

* **Packaging customization:** Custom bottle or cap designs may extend lead times due to specialized mold development or sourcing.

* **System complexity:** More complex line configurations or optional modules may require additional engineering and assembly time.

* **Order volume:** Larger order quantities may slightly increase overall production time.

* **Production workload:** Our current manufacturing schedule may also affect lead time depending on order volume at the time of confirmation.

Ready To Boost YourProductivity?

Contact Form

Thank you for your interest. If you have any inquiries, please fill out the form below. We will get back to you within 24 hours.