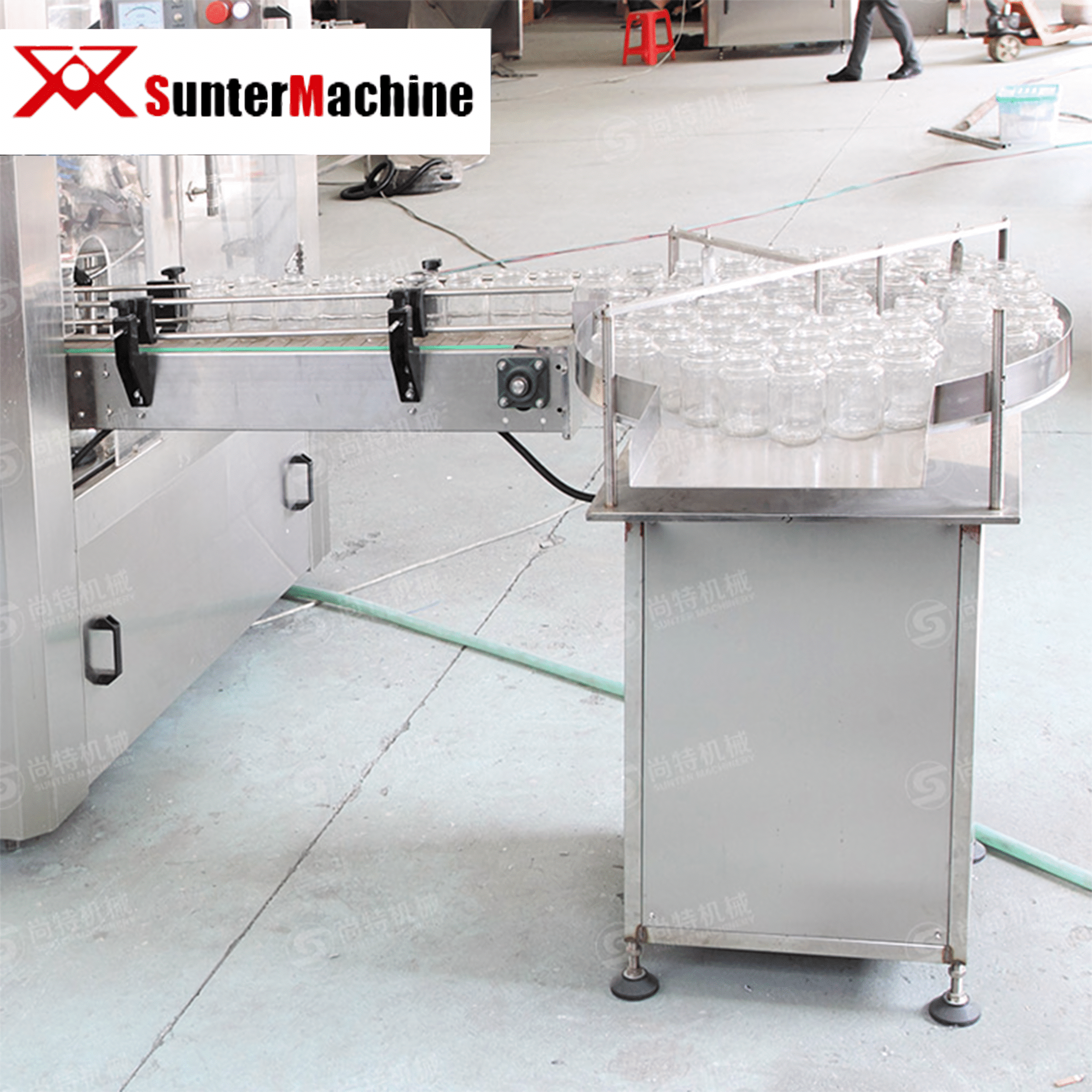

Bottle unscrambler

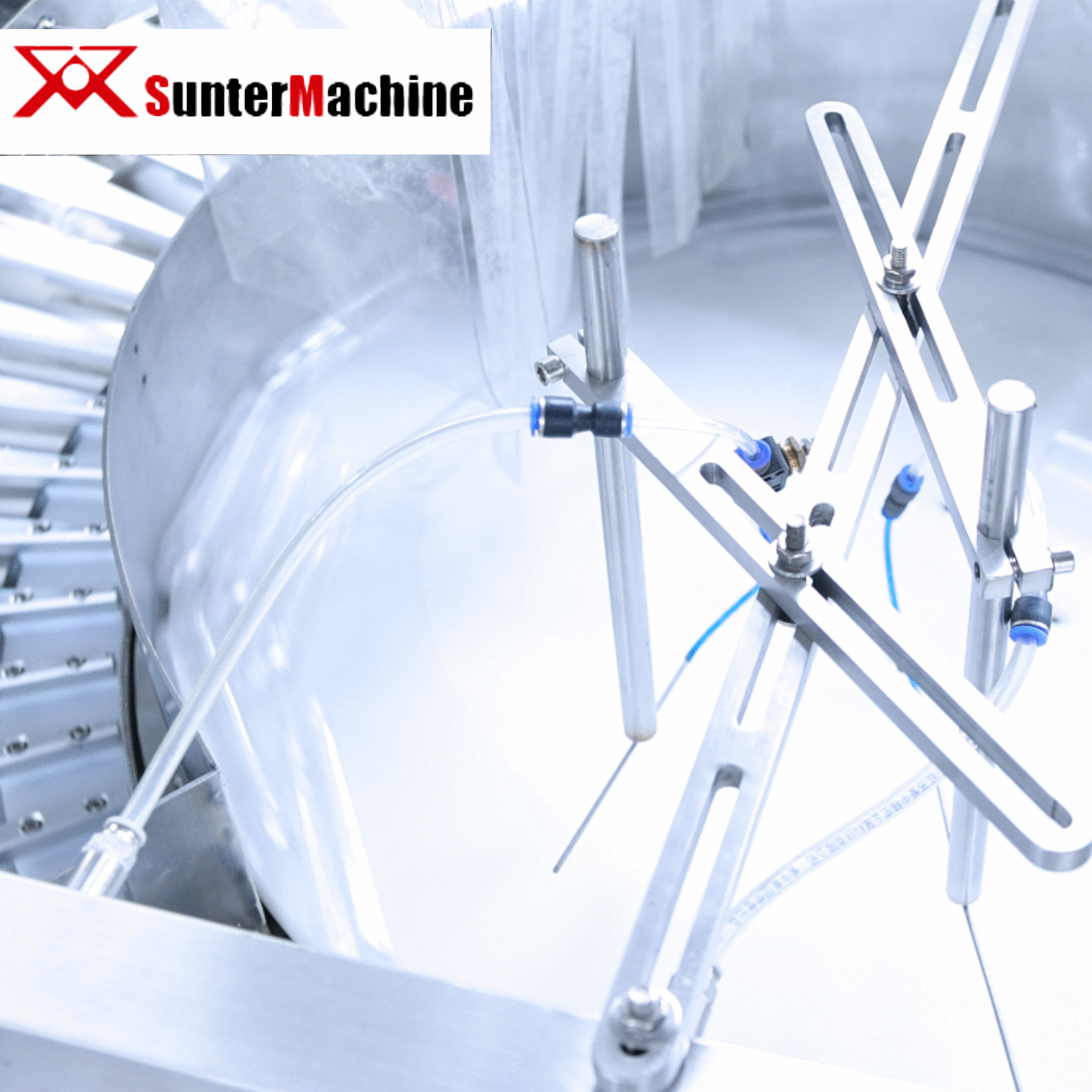

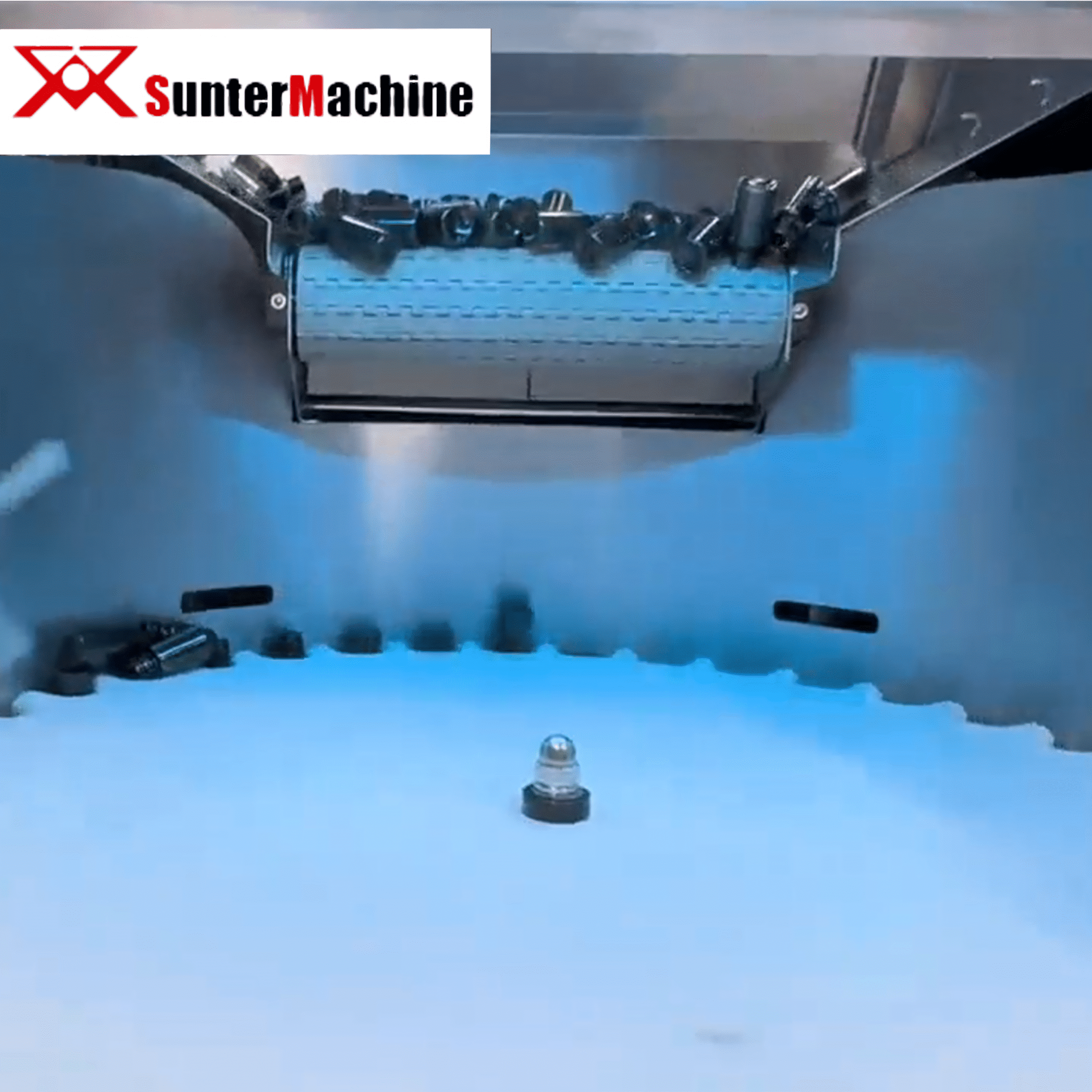

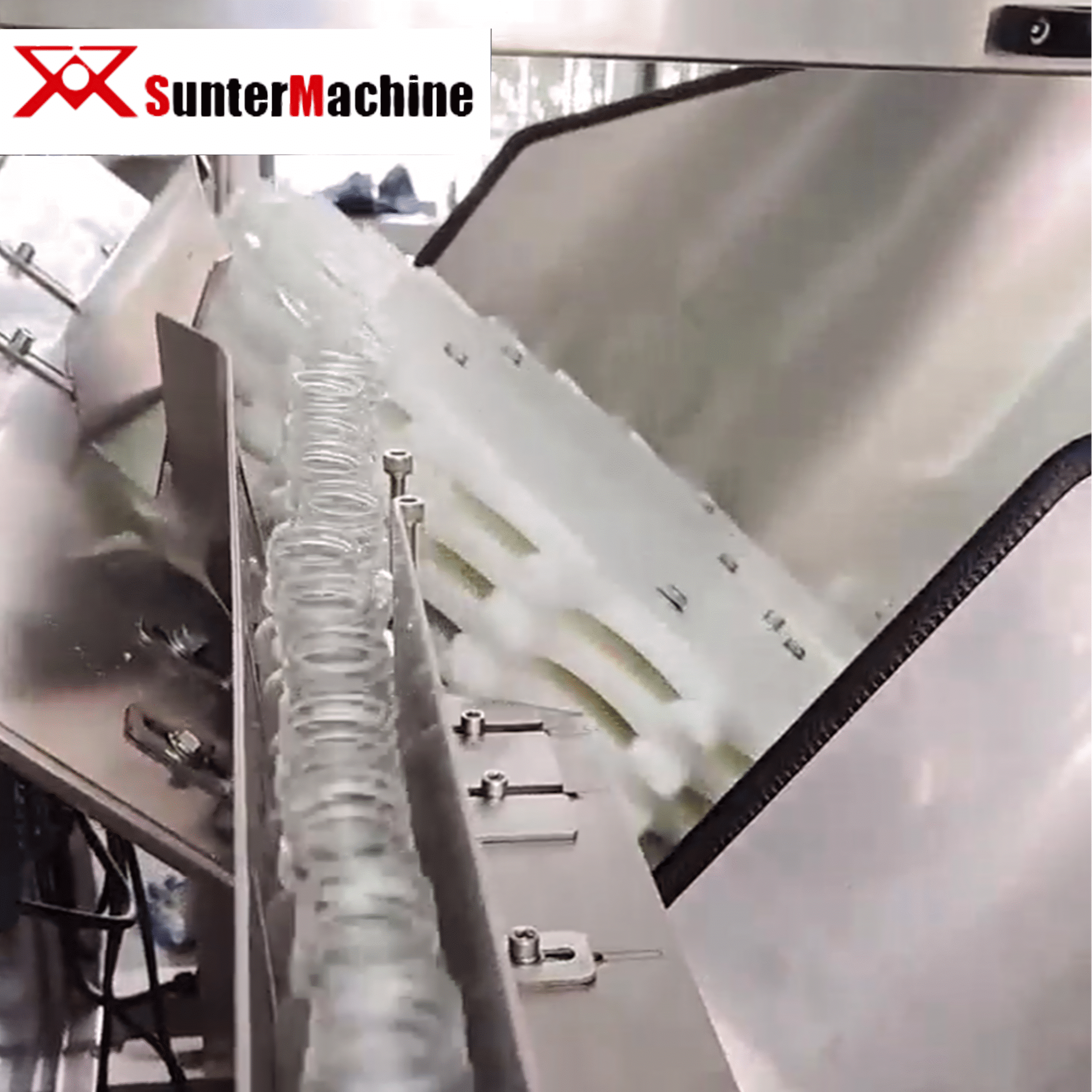

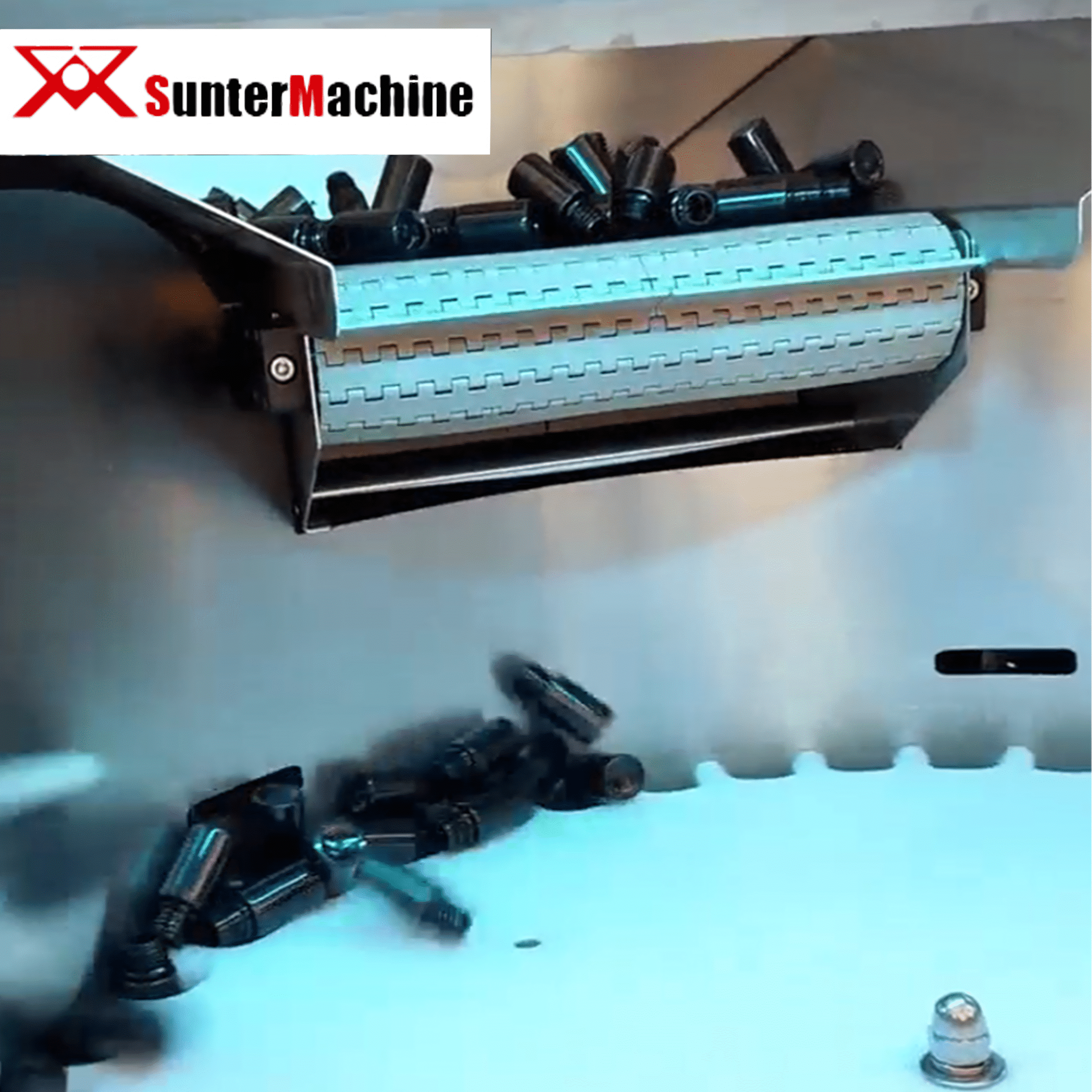

Automatically sorts and feeds empty bottles upright into the production line. Fast, stable, and suitable for various bottle shapes and sizes.

Your One-Stop Manufacturers For Bottle Sorting Solutions

Non-Standard Customization

100% Customization – Perfectly Tailored to Your Production Needs

12-Hour Online Support

Our Professional Team Is Always Ready to Solve Any Issues.

Customize Your Bottle Unscrambler in Just 5 Steps!

Step 2 Let us know the bottles, caps, and containers you intend to fill

What types of containers do you plan to use for filling?

Step 4 Dedicated After-Sales Support to Ensure Worry-Free Production

The after-sales services and technical support offered by Sunter team.

Step 1 Define Your Filling Capacity and Machine Requirements

What are your target volume, hourly output, and preferred filling system?

Step 3 Explore Real Custom Projects by Sunter – Direct from Our Factory Floor

Discover Sunter's Expertise Through Our Proven Machinery Cases.

Step 5 Customer FAQs – Everything You Want to Know Before Ordering

Find answers to common questions to help you make an informed purchase.

step 1

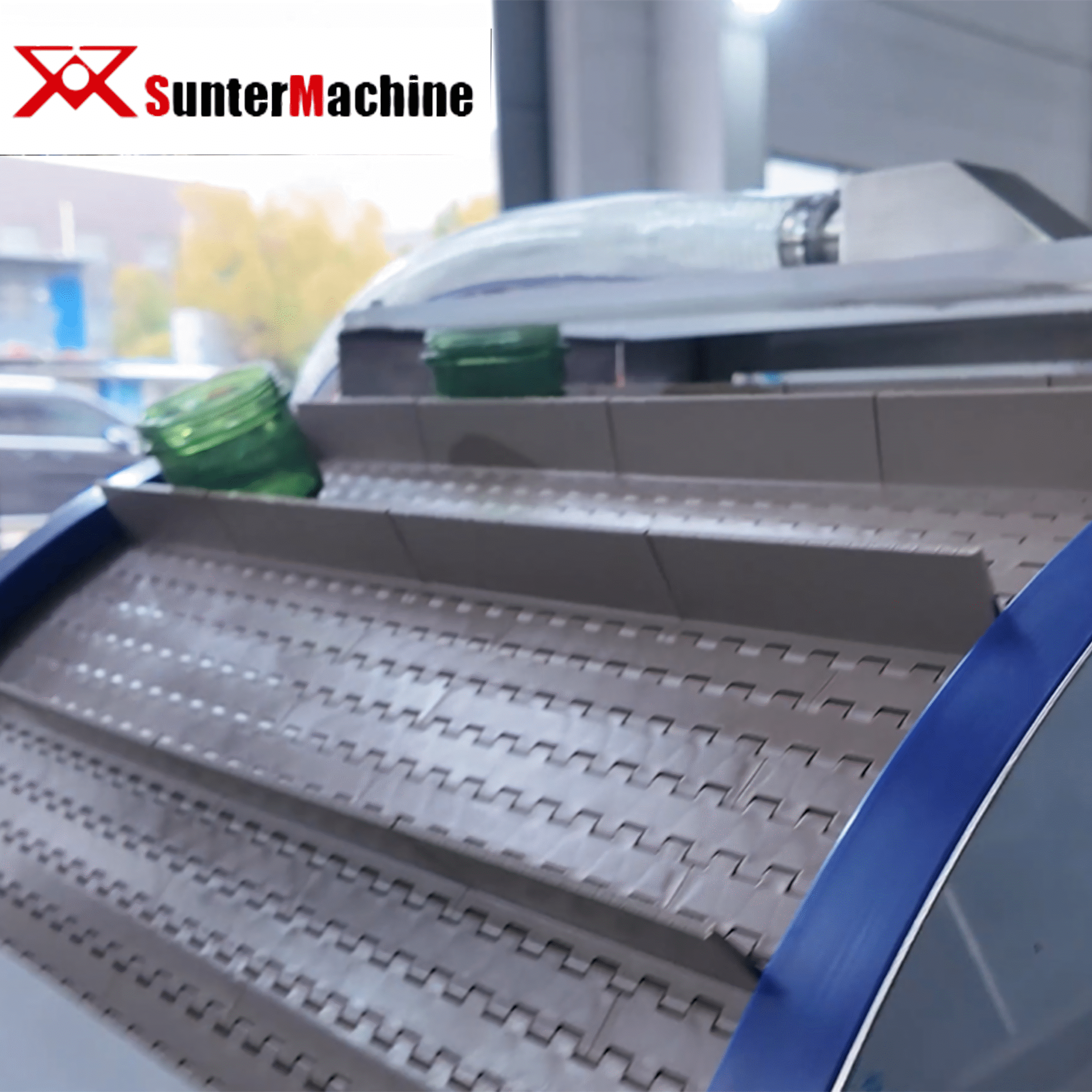

Explore Our Bottle Sorting Equipment

'BPH' = Bottles Per Hour (filling capacity).

Step 2

Tailor-Made Machines Based on Your Bottle Type – Precision Built for Your Product

Bottle material: glass, plastic, adaptable to various materials

Corporate Trust Us

step 3

Your Trusted Expert in Turnkey Filling Lines From China

20+ Years Of Experience

14 Patent Certifications

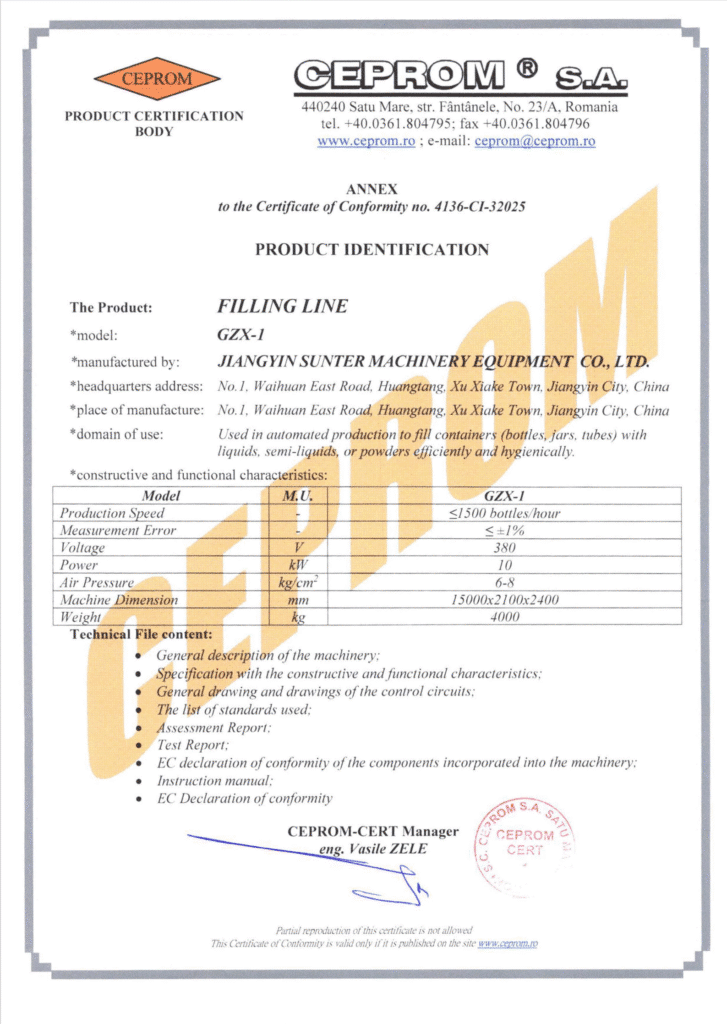

CE Certified

step 4

From Factory to Your Door – Hassle-Free Logistics Solutions

Packaging and shipping service

All machines are securely packed in export-grade wooden cases. We work with trusted logistics partners to ensure safe, on-time delivery by sea, air, or land.

precision installation and usage training

We provide clear installation guidance and hands-on training to ensure your team can operate the machine with confidence and efficiency from day one.

1-year full after-sales service

We offer a one-year warranty with full technical support, quick response, and spare parts assistance to keep your production running smoothly.

step 5

Customer FAQs – Want to Know More? Get in Touch with Us!

* **Semi-automatic bottle unscramblers** typically involve a lower initial investment and are ideal for businesses with limited budgets or smaller production volumes. These machines require more manual involvement, which may result in slightly higher training costs. However, they offer greater flexibility, making them easier to adapt to product changes or evolving production processes.

* **Fully automatic bottle unscramblers** are designed for high-efficiency, continuous production. While the upfront cost is higher, these systems significantly reduce manual labor and long-term operational costs. They are best suited for large-scale and standardized production environments. Advanced control systems and integrated sensors provide precise data tracking and enhanced quality control.

At **Sunter Machinery**, we work closely with our customers to understand their current operations and future development goals. Based on this comprehensive assessment, we recommend the most appropriate level of automation to ensure optimal performance and return on investment.

* **Clean all contact surfaces regularly** to prevent contamination and ensure smooth operation.

* **Inspect and lubricate all moving components** according to the lubrication schedule to minimize wear and reduce the risk of mechanical failure.

* **Check and tighten belts, chains, and other drive components** to maintain proper tension and alignment.

* **Follow the maintenance schedule provided by the manufacturer**, which includes routine checks, part replacements, and system calibrations.

By adhering to these maintenance guidelines, you can maximize equipment lifespan, minimize unplanned downtime, and maintain consistent production quality. Our technical team is also available to provide maintenance training and support tailored to your operation.

* **Startups and Pilot Projects**: We support emerging businesses launching new product lines or market-testing with a single machine.

* **Small to Medium Enterprises**: Ideal for companies looking to upgrade specific sections of their production line or expand gradually.

* **Custom Single Machines**: We offer tailored solutions even for single-unit orders, adapting each machine to your unique product characteristics, container specifications, and process requirements.

Whether you are in need of a fully integrated turnkey system or a standalone filling unit, Sunter Machinery is committed to providing reliable, high-performance equipment tailored to your exact needs.

* **Voltage**: e.g., 220V, 380V, 415V

* **Frequency**: 50 Hz or 60 Hz

* **Phase**: Single-phase or three-phase

We support standard power configurations used across Europe, North America, Asia, and the Middle East. For facilities located in regions with non-standard or unstable power conditions, we offer optional integration of voltage stabilizers or transformers within the equipment design.

Our engineering team will verify all electrical requirements prior to shipment and configure the system accordingly, ensuring the machine is ready for immediate installation with minimal on-site adjustment.

* **Wearing Parts and Operation Video**: Each shipment includes one year’s supply of essential wearing parts, along with a detailed operation tutorial video to assist your team in daily use and routine handling.

* **Operator Training**: We offer thorough training for your personnel, covering machine operation, basic maintenance, and troubleshooting procedures to ensure safe and efficient usage.

* **Technical Support**: Our technical team provides prompt assistance through phone, email, or remote diagnostics to resolve operational issues quickly and minimize downtime.

* **Warranty Service**:

* We offer **lifetime technical support** for all equipment.

* Within the **one-year warranty period**, we will replace or repair defective components free of charge. Customers are only responsible for shipping costs.

* Please note that parts damaged due to human error or misuse, as well as wearable and consumable parts, are not covered under warranty.

To provide a more accurate and tailored delivery schedule, we kindly request the following information:

* **Detailed specifications of bottles and closures**, including precise dimensions (length, width, and height)

* **Desired production line configuration**, including any optional modules or integrated systems

* **Throughput requirements**, such as the number of bottles per hour and volume per bottle

Several factors may influence the actual lead time, including:

* **Packaging material customization**: If your bottles or caps require unique designs or non-standard materials, additional sourcing time may be required.

* **Line complexity**: The complexity of the selected configuration and the number of modules can impact overall production time.

* **Order volume**: Larger or multi-unit orders may result in extended production schedules.

* **Current manufacturing workload**: Our factory’s production capacity at the time of order placement can also affect lead times.

Our sales and engineering teams will evaluate your specific requirements and provide a detailed delivery schedule accordingly.

Ready To Boost YourProductivity?

Contact Form

Thank you for your interest. If you have any inquiries, please fill out the form below. We will get back to you within 24 hours.