Planning Your Edible Oil Line: Are You Ready for the Reality Beyond the Hype?

Planning a new filling line is exciting, but hidden issues can derail it. Imagine your expensive new line sitting idle because it can’t handle a

Planning a new filling line is exciting, but hidden issues can derail it. Imagine your expensive new line sitting idle because it can’t handle a

Struggling with leaking 5-gallon buckets or drums? You’ve tightened the caps perfectly, but the seals fail. It’s a frustrating and costly problem that damages products

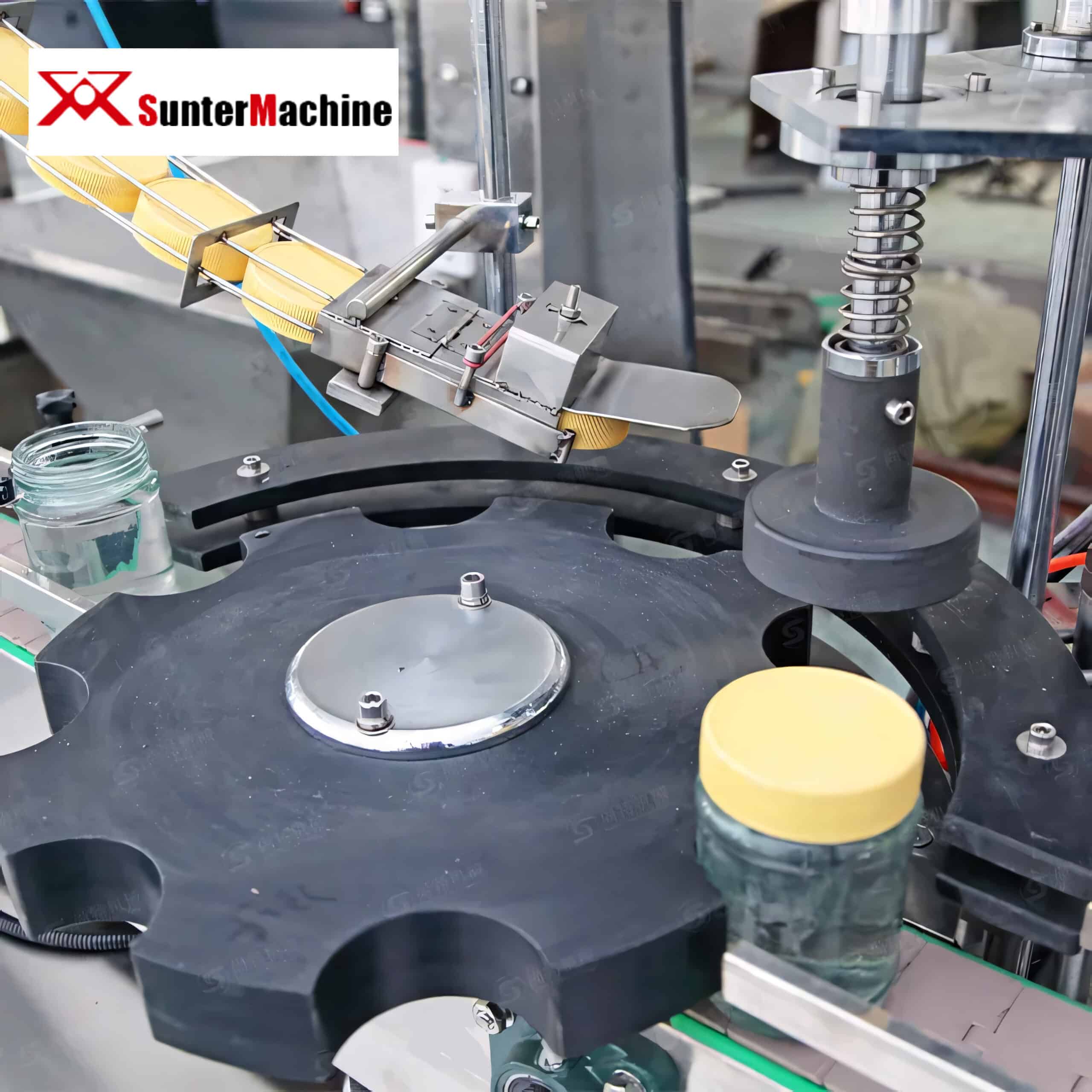

Wrinkled or peeling labels make your product look unprofessional. This can damage your brand’s reputation. Let’s solve these common labeling problems and ensure your product

How Can a Simple CheckliAre you tired of unexpected machine downtime? These sudden stops kill productivity and profits. A proactive maintenance checklist is the simple

Your fast packaging machine isn’t enough. Bottlenecks elsewhere on the line are crippling your true output. You need a complete, integrated system to unlock your

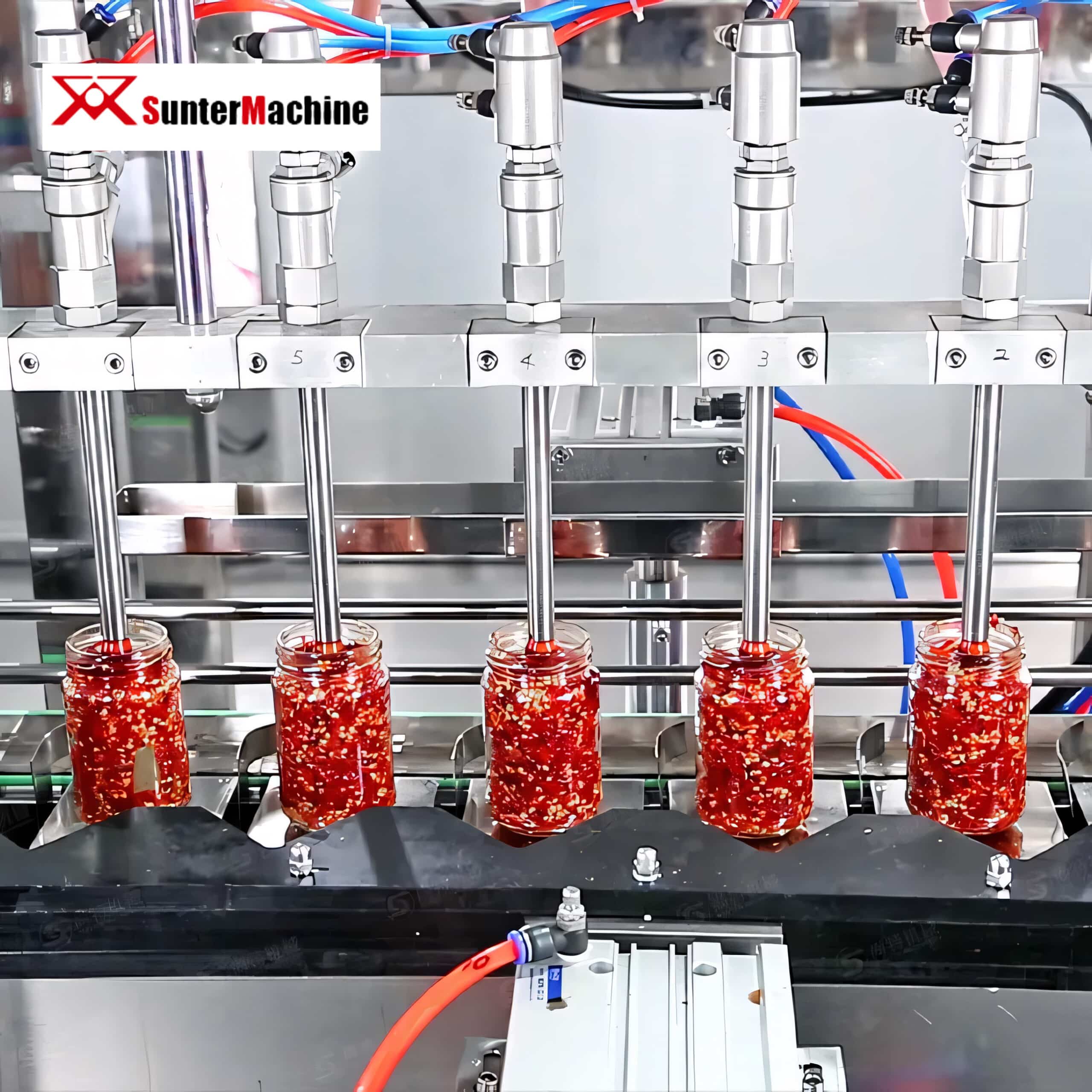

Your chunky sauce is your brand’s pride. But the wrong pump turns it to mush, destroying your product’s texture and reputation. How do you stop

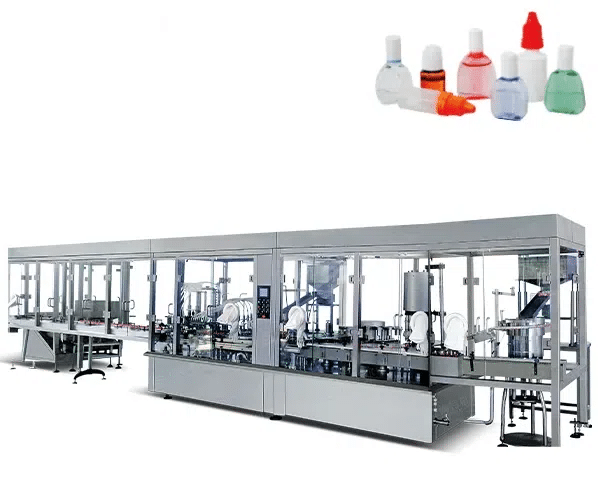

Struggling with inconsistent fill volumes in your production line? This fluctuation can affect patient experience and product trust, even when within official tolerances. It’s a

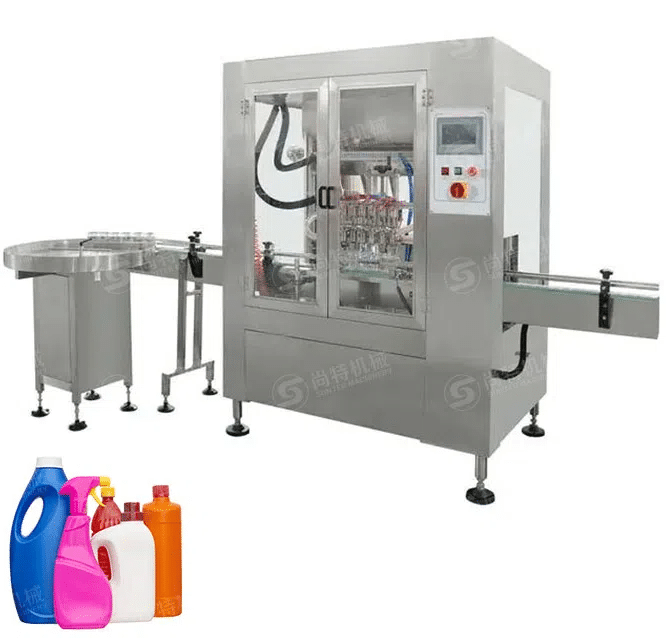

Pumping thick soaps and gels is tough. Wrong pumps cause waste and downtime. Selecting the right pump technology is the simple, powerful solution you need.

Filling liquids with different viscosities is a major challenge. Inaccurate fills lead to product waste and lost profits. Choosing the right technology is the key