Zero Contamination: Why are SS316L and CIP Systems Non-Negotiable for Syrup Filling?

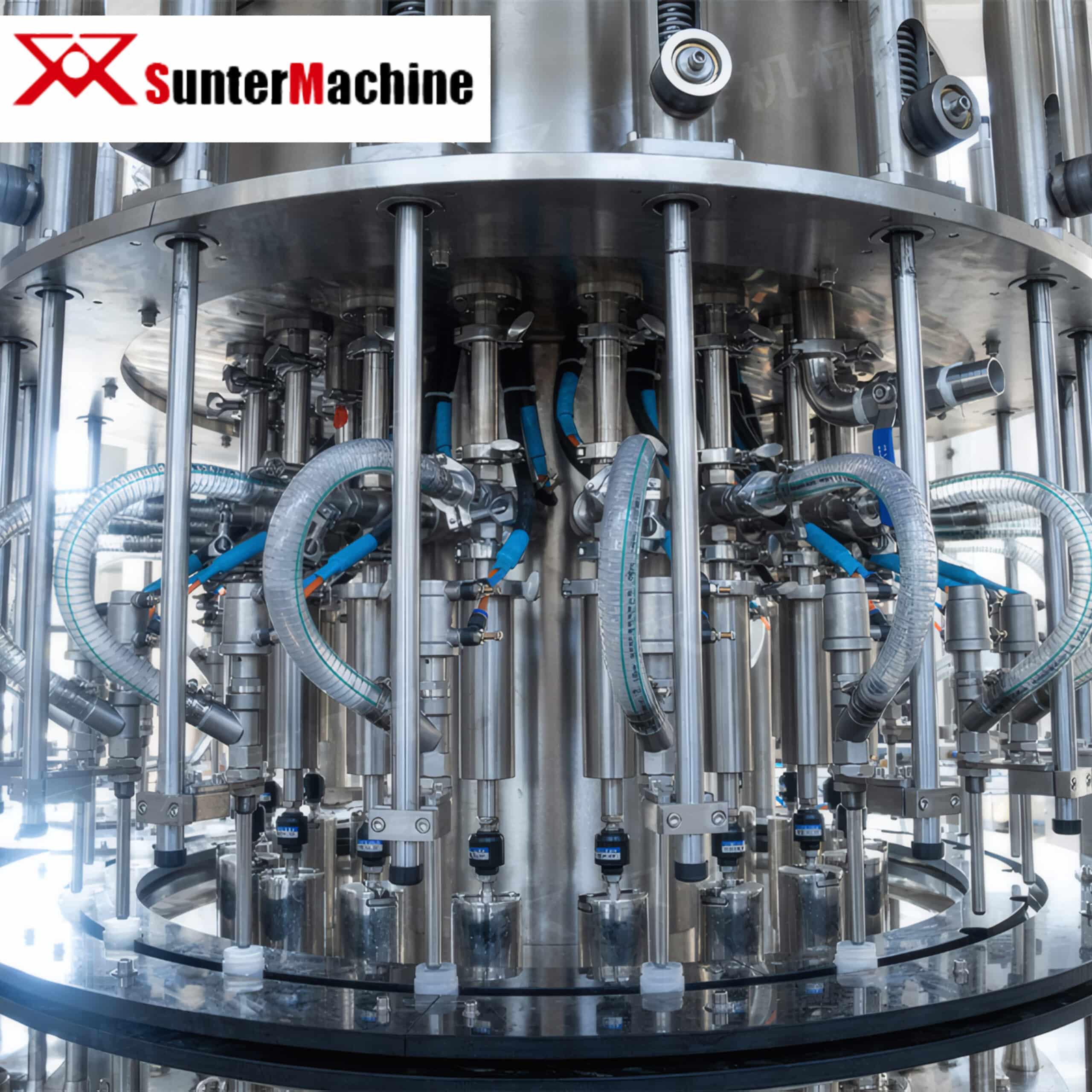

Struggling with contamination risks in your syrup filling line? Failing a GMP audit because of residue can be a nightmare. The solution lies in using

Struggling with contamination risks in your syrup filling line? Failing a GMP audit because of residue can be a nightmare. The solution lies in using

Struggling with foam during high-speed filling? This common problem causes inaccurate fills and product waste, slowing down your entire production line and hurting your bottom

Struggling to choose the right pump for your filling line? A wrong choice can lead to budget overruns and production headaches. Here are my secrets

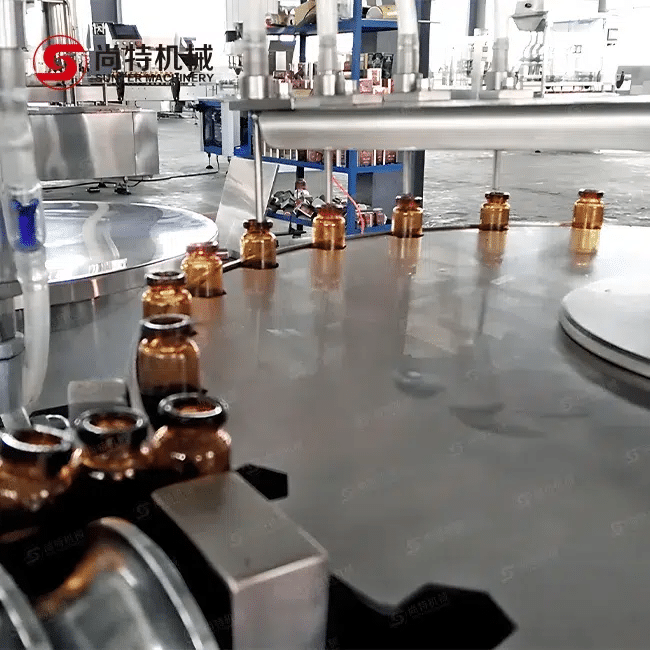

Honey bottling creates sticky drips and foam, wasting product and money. This messy process can ruin your efficiency. Let’s explore how precise engineering solves these

Choosing the wrong filling pump creates production nightmares. These issues with efficiency and cost can sink your project. I will help you pick the right

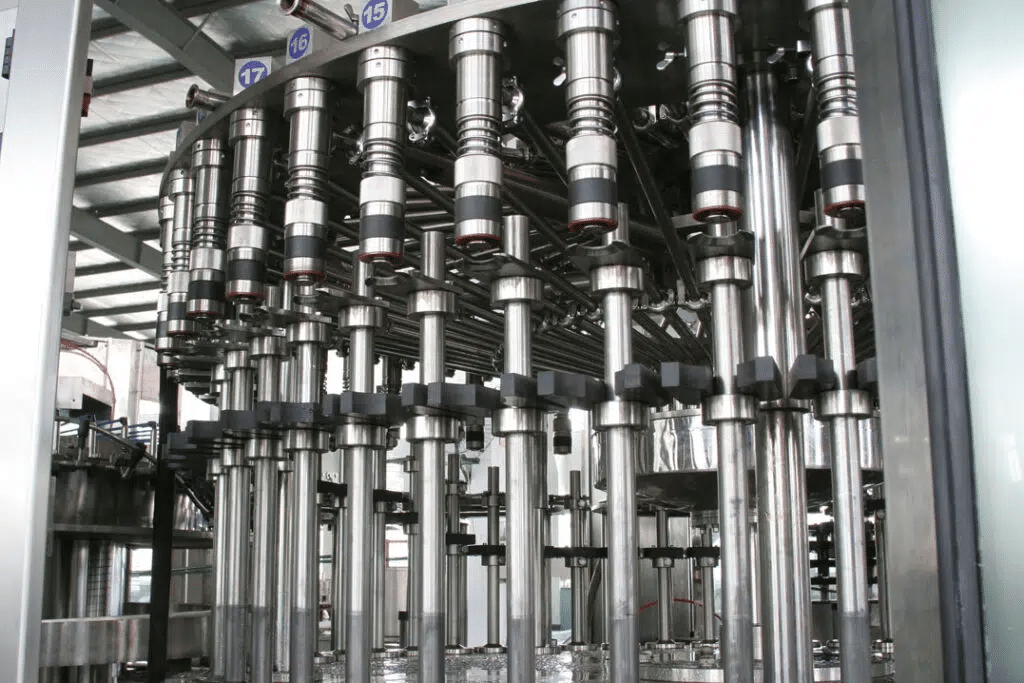

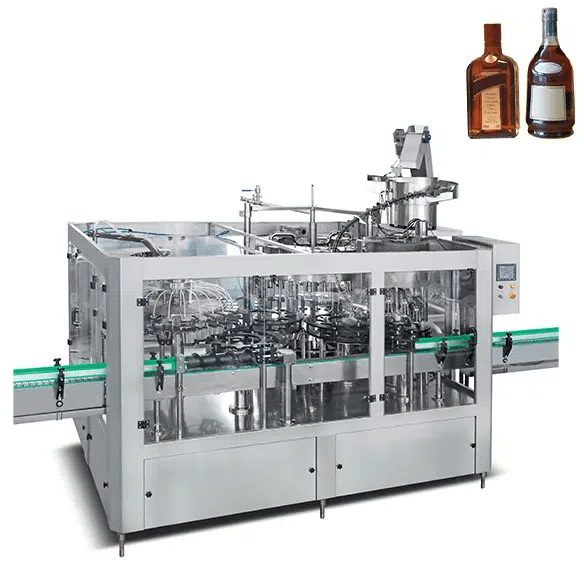

Struggling with uneven fill levels in your spirits? This inconsistency looks unprofessional and costs you money. I will help you solve this problem for good.

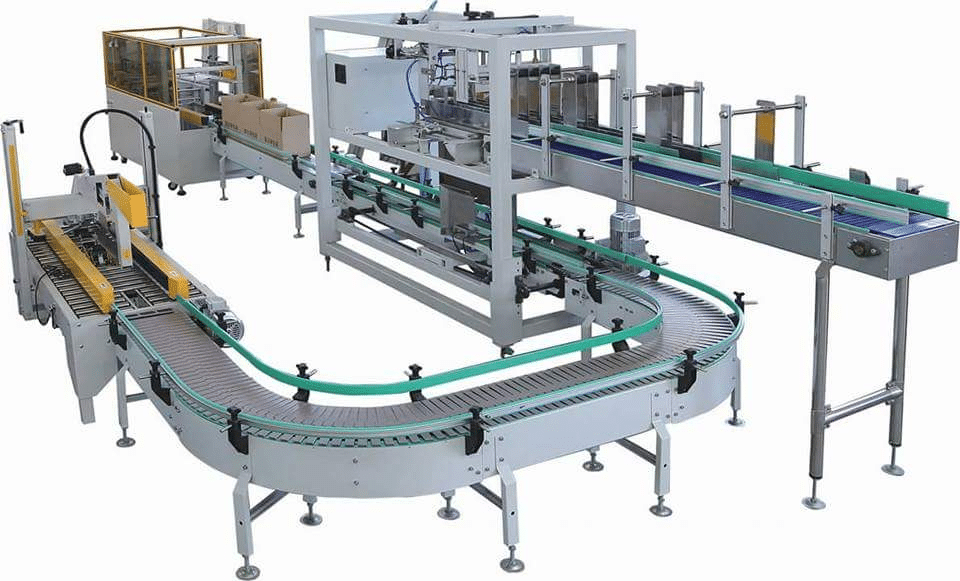

Planning your first automation project is exciting, but mistakes are expensive. Focusing only on single machines often leads to costly failures. It’s time to learn

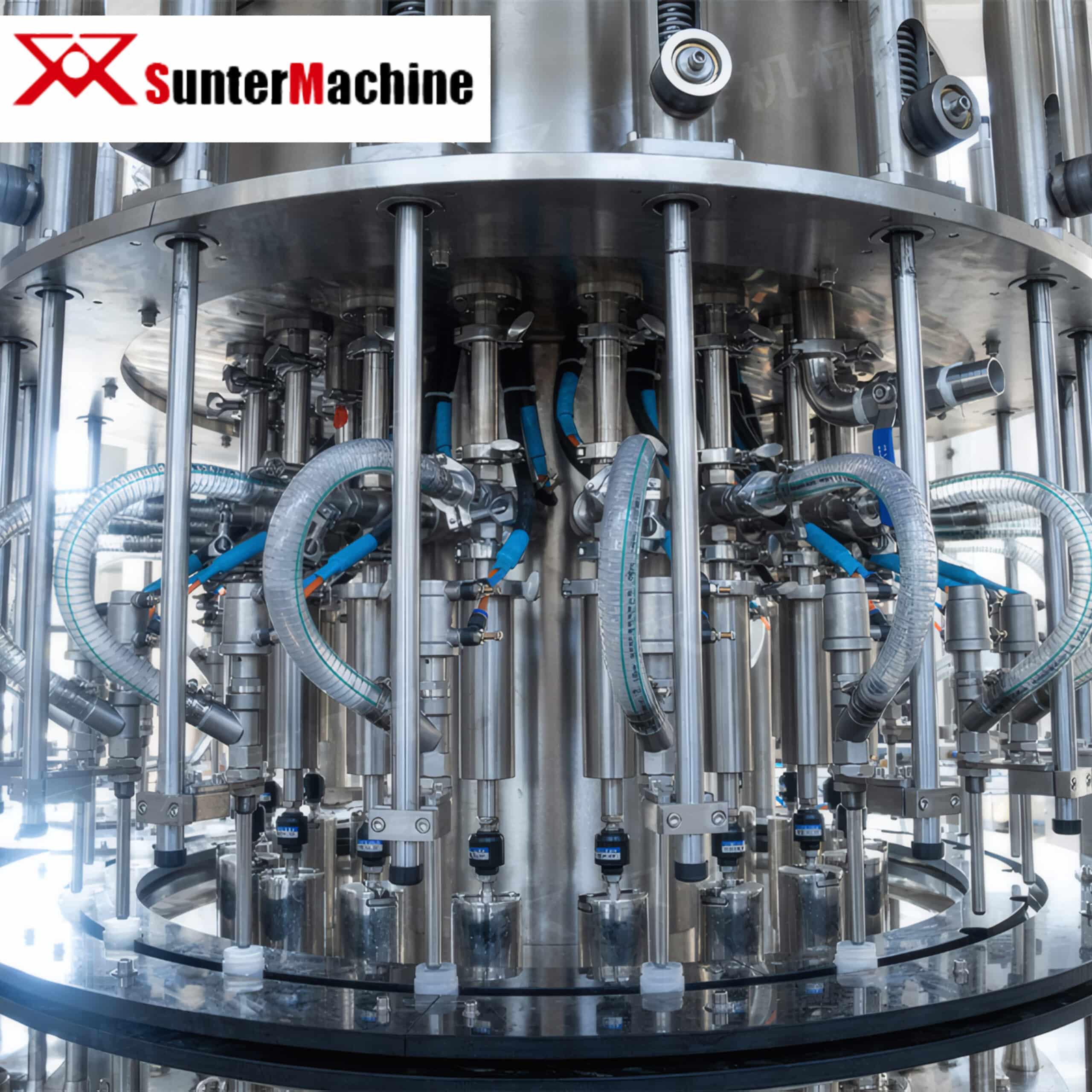

Your line starts perfectly, but now fills are inconsistent, causing waste and compliance risks. The secret to lasting accuracy is mastering the hidden physical variables

Are your syrup filling volumes inconsistent? This frustrating issue wastes product and hurts your bottom line. The root cause is often hidden, but the solution